INTRODUCTION

Brazing and Soldering

Brazing and Soldering

Brazing and soldering are critical joining processes used to create strong, reliable bonds across various industries—ranging from electronics and aerospace to automotive, plumbing, and fine metalwork. Although both methods rely on filler metals to form joints without melting the base materials, each technique has distinct temperature ranges, joint properties, and applications.

BRAZING AND SOLDERING

Comparison of Brazing and Soldering

Comparison of Brazing and Soldering

Brazing

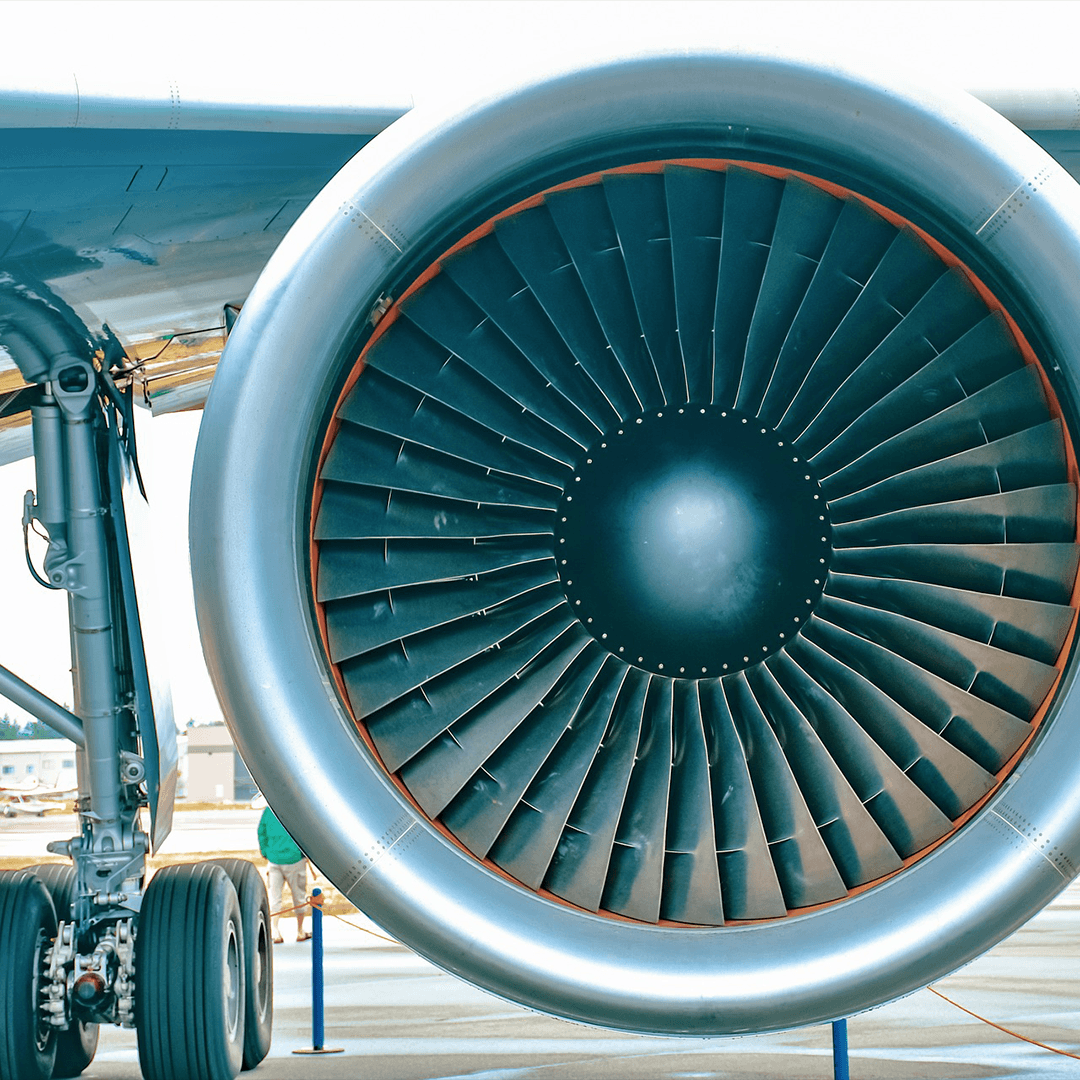

Typically occurs at temperatures above 450°C (842°F). The filler metal flows into the joint by capillary action, creating durable bonds with excellent mechanical strength and corrosion resistance. Commonly utilized in high-temperature or high-stress environments, brazing is favored in aerospace, automotive, and HVAC systems.

Soldering

In contrast, operates below 450°C. Though it forms weaker joints compared to brazing, its lower process temperature makes soldering ideal for heat-sensitive components such as electronic circuit boards and delicate assemblies. Despite lower mechanical strength, soldering ensures reliable electrical conductivity and sealed joints in plumbing and electronics.

BRAZING AND SOLDERING

Applications of Brazing and Soldering

Brazing and soldering are used across multiple industries to create strong, reliable connections in components that demand durability, conductivity, and corrosion resistance. These processes play a vital role in ensuring structural integrity, electrical performance, and long-term stability in both high-stress and delicate applications.

Filler metal selection is determined by operating temperature, mechanical strength, corrosion resistance, and process compatibility. These factors are detailed in the respective brazing and soldering alloy sections.

Brazing Alloys

01

Silver-based (Ag-Cu-Zn) alloys:

Used for their excellent wetting characteristics and thermal conductivity.

02

Nickel-based alloys

Ideal for high-temperature and oxidation-resistant applications.

03

Copper-phosphorus (Cu-P) alloys

Commonly used for copper and brass joining without the need for flux.

04

Aluminum-silicon alloys

Commonly used for copper and brass joining without the need for flux.

05

AgCuZn

A high-performance brazing alloy with excellent fluidity and corrosion resistance, making it ideal for joining dissimilar metals in demanding environments.

METAL POWDERS

Brazing Processes

Brazing utilizes various processes to achieve strong, high-quality joints, particularly when using metal powders as filler materials. The following are six key brazing techniques that rely on powder-based fillers. Each of these techniques provides unique advantages in terms of precision, strength, and application compatibility, making brazing a versatile and essential joining process in modern manufacturing.

Powder Injection Brazing

This process involves injecting brazing powders into the joint area, typically using a carrier gas or binder. It is widely used in the aerospace and automotive industries. Common alloys: Ni-based (Ni-Cr-B-Si), Ag-based (Ag-Cu-Zn), and Cu-based (Cu-P).

Furnace Brazing

A controlled-atmosphere or vacuum process where pre-placed brazing powder melts and flows into the joint. Ideal for batch production and complex assemblies. Common alloys: Ni-based (Ni-Cr-B-Si), Cu-based (Cu-Sn), and Al-Si alloys.

Torch Brazing with Powder Paste

Brazing paste containing fine metal powders and flux is applied to the joint and heated with a gas torch. Used for localized repairs and smaller assemblies. Common alloys: Ag-Cu-Zn, Cu-P, and Sn-Ag-Cu.

Induction Brazing with Powders

Brazing paste containing fine metal powders and flux is applied to the joint and heated with a gas torch. Used for localized repairs and smaller assemblies. Common alloys: Ag-Cu-Zn, Cu-P, and Sn-Ag-Cu.

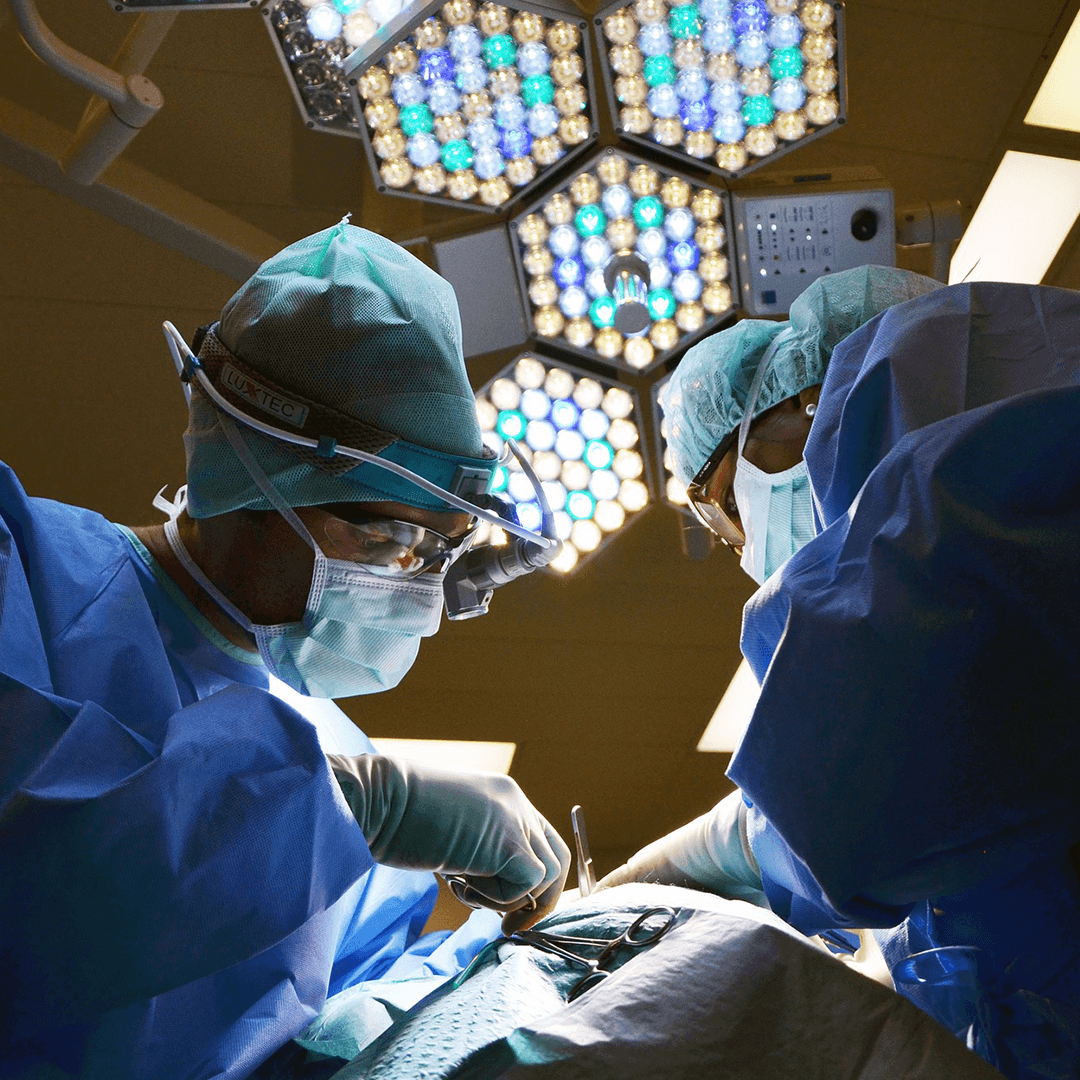

Vacuum Brazing

A high-purity process that removes oxidation by brazing in a vacuum furnace. It is ideal for aerospace, medical, and electronic components requiring high joint integrity. Common alloys: Ti-based (Ti-Cu-Ni), Ni-based (Ni-Cr-B-Si), and Ag-Cu-Zn.

Spray Brazing

A high-speed process where atomized brazing powder is sprayed onto the joint and melted using a heat source. This method is ideal for large surface applications such as heat exchangers. Common alloys: Cu-based, Ni-based, and Al-Si alloys.

Soldering Alloys

01

Tin-lead (Sn-Pb) alloys

Traditional compositions that offer excellent wetting but are being phased out for environmental reasons.

02

Lead-free tin-based alloys

These include combinations of tin (Sn) with silver (Ag), copper (Cu), and bismuth (Bi) to meet industry regulations.

03

SAC-305 (Sn-3.0Ag-0.5Cu)

A widely used lead-free solder alloy, especially in electronics, known for its relatively high mechanical reliability and good wetting properties.

04

SnAgCu (various ratios)

Commonly including compositions such as Sn-3.8Ag-0.7Cu and Sn-3.0Ag-0.5Cu, providing enhanced reliability, improved mechanical strength, and increased creep resistance compared to tin-lead alloys.

05

SnBi

A low-temperature soldering alloy, particularly suitable for applications requiring reduced thermal stress on components.

METAL POWDERS

Soldering Processes

Soldering powders are widely used across different industrial applications, and various processes ensure precise and high-quality joints:

Powder Soldering (Paste Soldering)

Utilized in both soft and hard soldering, solder powders such as Sn96.5Ag3.5 or SAC305 are mixed into pastes for precise applications, particularly in electronics.

Laser Soldering

A fine and detailed soldering process using focused laser energy, often applied in microelectronics, employing fine SnAgCu alloys such as SAC305.

Ultrasonic Soldering

A specialized technique where no flux is used, commonly involving pure tin-based alloys such as SnCu, ensuring strong joints in applications requiring high reliability.

Exothermic Soldering

This process employs a chemical reaction between metal powders, such as aluminum and metal oxides, to generate intense heat, facilitating the soldering of metals without external heat sources.

REQUIREMENTS

Requirements for Brazing and Soldering Powders

Achieving reliable joints in brazing and soldering hinges on the physical and chemical properties of the filler metal powders. Key considerations include:

Particle Size Distribution

Generally, soldering powders range from 10–45 µm for improved flow and melting behavior, while brazing powders can range from 20–150 µm depending on the process.

Particle Shape

Spherical, satellite-free particles enhance flowability packing density and reduce defects within the joint.

Surface Oxidation & Purity

Minimizing oxide layers ensures better wetting and adhesion, promoting stronger, more reliable joints.

Flow Characteristics

Uniform distribution, free flow to ensure the filling of tight gaps, and wetting are crucial for reducing porosity and ensuring consistent bond quality.

AMAZEMET - your partner for developing novel solder and brazing powders

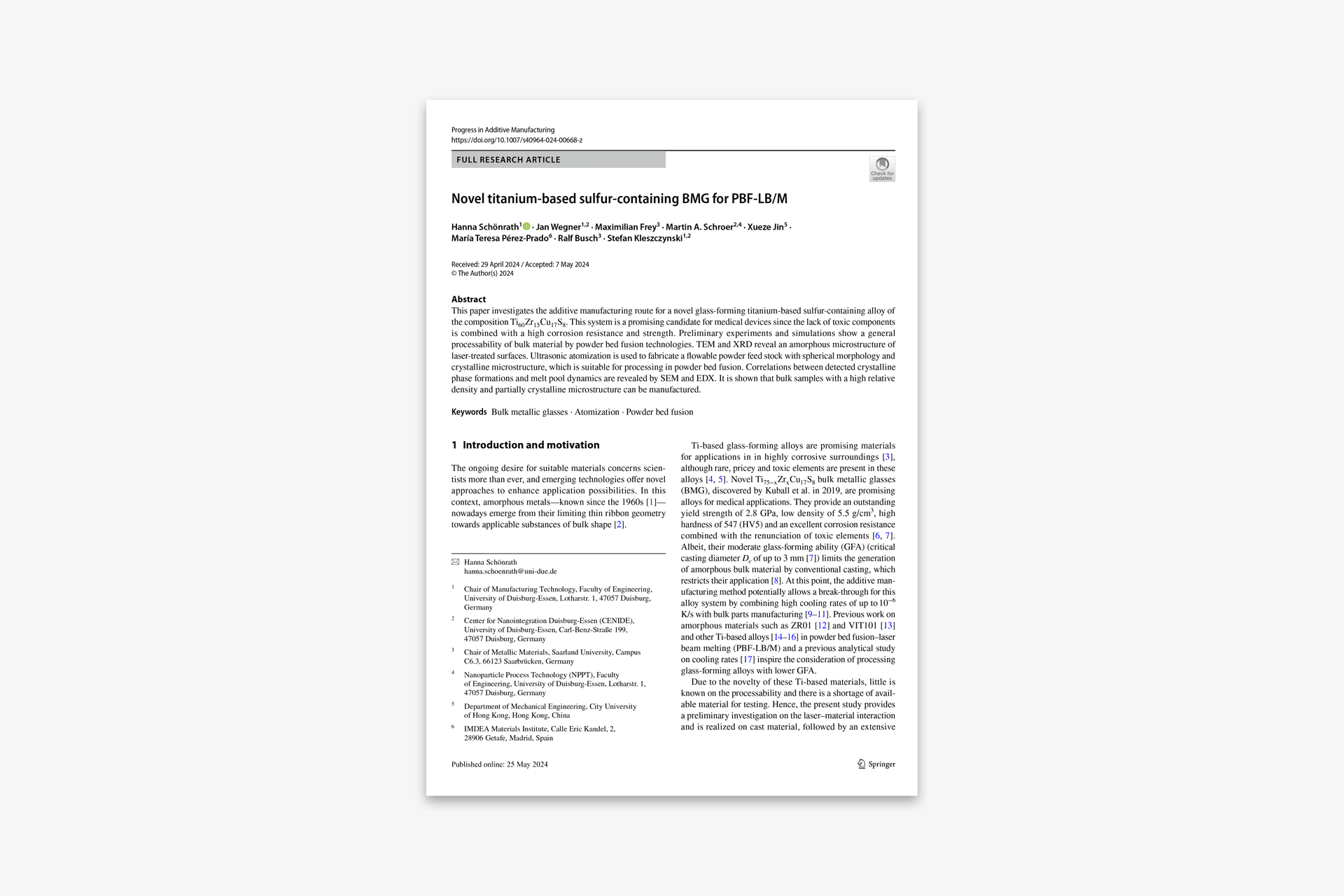

AMAZEMET’s team of material scientists, including PhDs and PhD students, actively contributes to the advancement of brazing and soldering technologies. Their research focuses on optimizing powder feedstock properties, improving joining efficiency, and developing novel filler alloys for high-performance applications.

Through collaborations with research institutions and industrial partners, AMAZEMET supports innovation in powder metallurgy, refining material properties for superior bond strength and thermal stability. Their expertise spans from powder synthesis to advanced metallurgical processing, ensuring high-quality solutions for cutting-edge applications.

In addition to providing customized powder solutions, AMAZEMET actively engages in joint research projects, working alongside academic and industrial partners to develop next-generation brazing and soldering materials. By participating in funded collaborations, consortia, and technology programs, AMAZEMET contributes to scientific advancements in joining technologies, bridging the gap between research and industrial applications. Our team welcomes collaboration opportunities that push the boundaries of material science and metallurgical engineering.

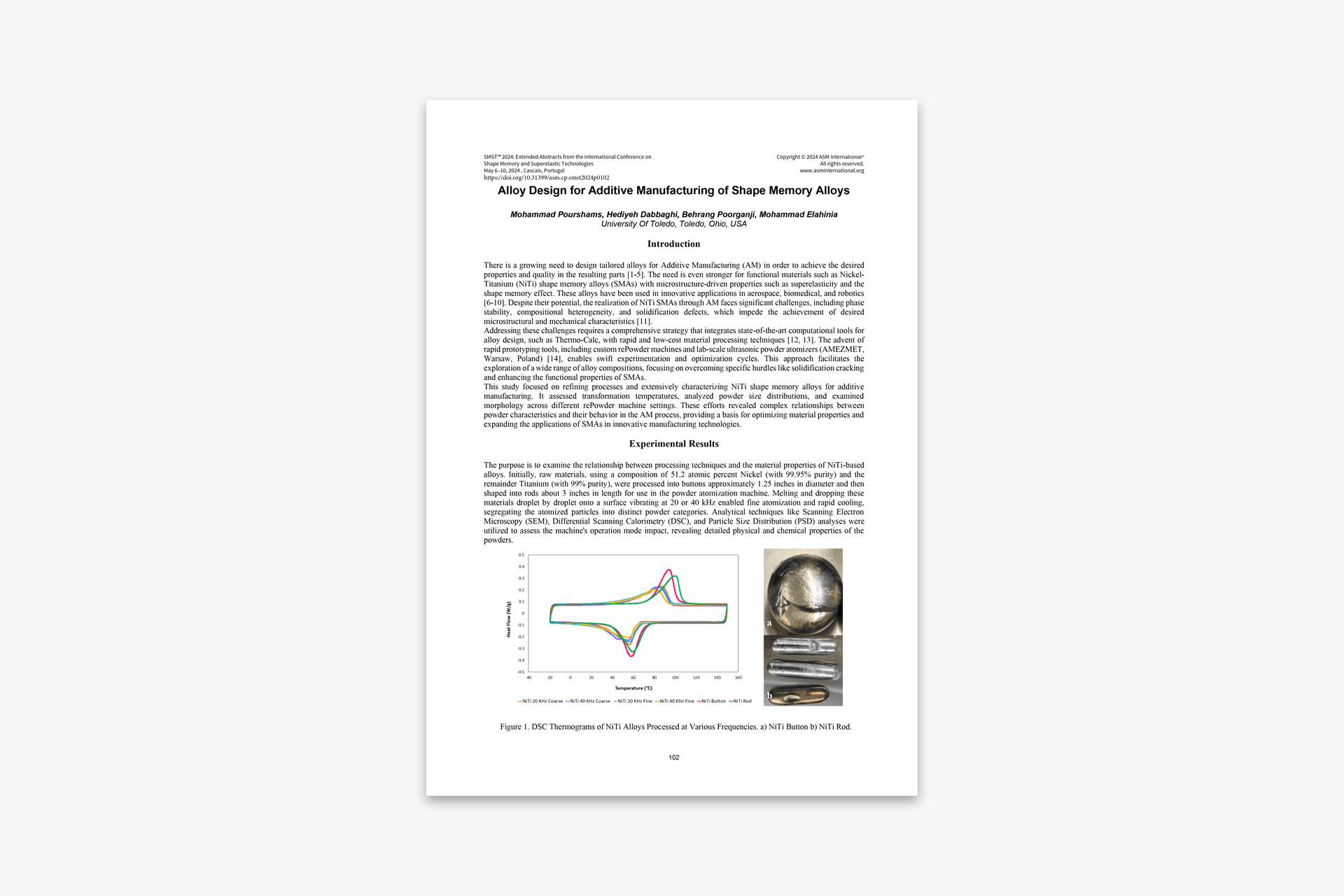

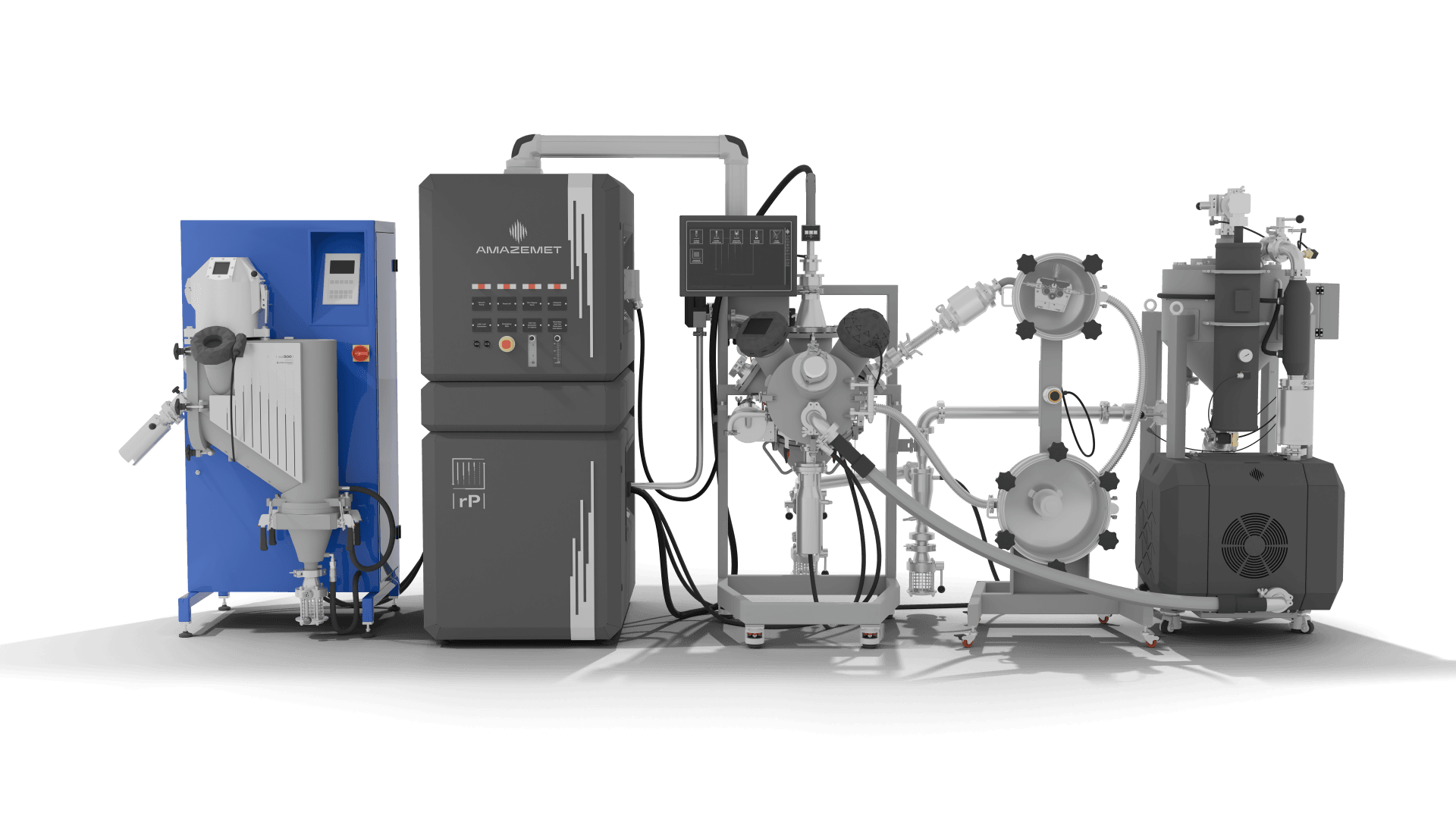

Ultrasonic Atomization: Advancing Alloy Development for Brazing and Soldering

Ultrasonic atomization offers a groundbreaking approach to alloy development for brazing and soldering, addressing key limitations of traditional gas atomization techniques. By leveraging an induction module, AMAZEMET’s rePowder system enables in-situ alloying and precise powder size distribution (PSD), making it a superior choice for research and development applications.

Unlike industrial-scale gas atomization, which requires significant investments in expensive inert gases (Argon, Nitrogen, or Helium) and operates under high pressures (up to 50 bar or 5 MPa), ultrasonic atomization is a more efficient and cost-effective alternative, particularly for R&D environments. Key advantages include:

- In-Situ Alloy Development: Enables real-time blending of elemental powders, facilitating the creation of novel soldering and brazing compositions tailored to specific research needs.

- Narrow Powder Size Distribution: Ensures optimized powder flow and controlled particle size, enhancing joint integrity and wetting behavior.

- Minimal Resource Requirements: Operates at lower gas consumption, significantly reducing operational costs compared to traditional gas atomization.

- Compact and Accessible Setup: Unlike large-scale gas atomization facilities, ultrasonic atomization systems are ideal for laboratory settings, requiring less space and technical expertise.

- Higher Material Efficiency: Achieves better yield for fine powder fractions, essential for high-performance brazing and soldering applications.

By integrating ultrasonic atomization into the R&D process, material scientists and engineers can explore new alloy compositions while maintaining precise control over powder characteristics, leading to improved performance and sustainability in brazing and soldering technologies.

Feel free to ask any questions!

OUR CUSTOMERS

Trusted by Innovators Worldwide

AMAZEMET is proud to collaborate with a diverse range of clients who trust our cutting-edge solutions to advance their projects. rePOWDER is currently being used to atomize novel powder compositions in:

SERVICES

AMAZEMET Atomization Services: The Advantage of Custom Powder Ordering

To accelerate your research and production processes, AMAZEMET offers comprehensive atomization services that allow you to order customized brazing and soldering powders tailored to your specific needs. By utilizing our powder ordering form, researchers and industrial partners can streamline the acquisition of high-quality metal powders optimized for various joining applications.

Advantages of AMAZEMET Atomization Services

- Tailor-Made Alloy Compositions: Design and order custom brazing and soldering powders with precise chemical compositions, optimized for your specific application.

- Consistent and Controlled Powder Morphology: Ultrasonic atomization ensures high sphericity, satellite-free particles, and uniform powder size distribution for superior flowability and joint quality.

- Cost-Effective Small Batch Production: Unlike large-scale gas atomization, AMAZEMET enables economical small-batch production, ideal for R&D and specialty applications.

- Flexible Feedstock Options: Process a wide range of materials, including elemental powders, pre-alloyed materials, and customized powder blends.

- Rapid Lead Times: Minimize downtime and accelerate development cycles with efficient powder production and lead times as low as 1 month for custom pwoder compostions.

- Sustainable Powder Solutions: Reduce material waste and cost by re-atomizing or modifying existing powders, enabling a closed-loop production system.

Partner with AMAZEMET for Your Brazing and Soldering Needs

AMAZEMET’s application engineers are ready to assist you in developing custom brazing and soldering powders tailored to your specific needs. Whether you require precise control over alloy composition, optimized powder properties, or specialized processing recommendations, our experts provide hands-on support for your research and industrial applications.

Our team works closely with clients to refine material properties, enhance joint performance, and streamline powder selection for brazing and soldering processes. With a focus on high-quality production, cost-effective small-batch atomization, and sustainability, AMAZEMET ensures superior results for cutting-edge joining technologies.

Contact our application engineers today to discuss your project requirements and explore how our tailored solutions can advance your brazing and soldering applications.

01

Let’s talk about closing the loop in your manufacturing process with our metal research multitool – rePOWDER.

02

Let’s develop the perfect powder for your brazing or soldering processes – reach out to our experts, by request a quote for your powder requirements.