Technical University of Munich: Future-Proof Equipment for Advanced Research | Case Study

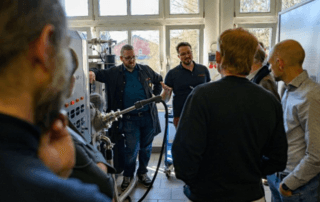

Universities and research institutes today face the challenge of quickly changing research directions and the need to adapt their equipment to new projects, often within tight budget constraints. AMAZEMET’s rePOWDER ultrasonic atomization system addresses this by providing an open platform designed for modular expansion. This allows institutions to start with a core system and expand their capabilities as research needs evolve and funding becomes available. The journey of the Technical University of Munich (TUM) with rePOWDER is a prime example of this principle, showing how upgradability supports innovation and protects the long-term value of research investments.

AMAZEMET IN NUMBERS | CASE STUDY

Since our foundation in 2019 as a dynamic spin-off from the prestigious Warsaw University of Technology, we at AMAZEMET have rapidly established ourselves as key innovators in the additive manufacturing (AM) and advanced materials sector. In just six dynamic years (as of May 16, 2025), we have demonstrated remarkable growth and technological prowess, driven by our mission to empower scientists and engineers worldwide with cutting-edge solutions for material development and processing. We are proud that despite numerous market perturbations, our company has remained profitable and is committed to sustainable development. This case study highlights our journey, impactful innovations, and the significant milestones we've achieved.

Chemnitz University of Technology: Partnership and Persistence in Securing Funding | Case Study

At AMAZEMET, we understand that the path to groundbreaking scientific discoveries often involves a lengthy and demanding process of securing funding. Our mission extends beyond providing innovative technological solutions; we strive to be a supportive partner for scientists at every stage of their journey. The case study of our collaboration with Chemnitz University of Technology (CUT) and the implementation of the rePOWDER system perfectly illustrates this approach.

Recycling of Ti alloy machining chips | Case study

Discover how arcMELTER efficiently transforms CNC machining chips into high-quality ingots for severe plastic deformation (SPD). This case study highlights the use of a getter for inert atmosphere purification before homogenization. Learn about this sustainable, cost-effective closed-loop approach to metal production and material valorization.

Alloy preparation from irregular powder | Case study

Learn how arcMELTER transformed poorly flowing irregular powder into spherical feedstock suitable for Direct Energy Deposition. This case study details how the process also enabled alloy homogenization with an additional element, improving thermal stability and precipitation hardening, unlocking new possibilities for advanced component manufacturing.

Custom master alloy preparation | Case study

Explore how arcMELTER facilitated the creation of a custom Mg-25%Ag master alloy, bypassing temperature limitations and evaporation issues of induction melting. This case study demonstrates a novel approach to precise alloying with pure elements, offering greater control and flexibility for material property tailoring without relying on commercially available master alloys. Discover the benefits for mechanical, corrosion, and thermal properties.