Freedom in Metal AM Develompent & Production

Take Your Chemical Materials to the Next Level with AMAZEMET

The chemical industry is at the forefront of material innovation, requiring precise and high-performance powders for a wide range of applications, including catalysis, coatings, and advanced manufacturing. The ability to tailor particle morphology, surface area, and reactivity is crucial for optimizing chemical processes and enhancing product performance. Advanced manufacturing techniques, such as ultrasonic atomization and plasma evaporation, enable the production of high-purity powders and nanoparticles, opening new possibilities in material science and industrial applications.

INTRODUCTION

Innovative Powder Technologies for the Chemical Sector

The chemical industry increasingly relies on advanced materials to enhance reaction efficiency, and material stability. Powder-based materials play a critical role in catalysis, controlled-release formulations, and high-precision surface treatments. By leveraging ultrasonic atomization and high-vacuum heat treatment, AMAZEMET provides high-purity, customized powders tailored for chemical applications requiring controlled solubility, specific surface characteristics, and reactivity.

ENERGY INDUSTRY

Key Challenges in Chemical Materials

Key Challenges in Chemical Materials

The chemical industry continuously pushes the boundaries of material performance, requiring advanced powders with tailored properties for safety, efficiency, and precise control over reactions. Meeting these demands calls for innovative approaches to powder design, from particle size control to complex core-shell structures.

The chemical industry continuously pushes the boundaries of material performance, requiring advanced powders with tailored properties for safety, efficiency, and precise control over reactions. Meeting these demands calls for innovative approaches to powder design, from particle size control to complex core-shell structures.

Processing of Reactive Materials

Many chemical applications require powders with highly controlled reactivity, demanding precise production methods to ensure safety, consistency, and performance.

Surface Area and Solubility Control

The ability to manufacture spherical powders with defined particle size distribution and surface area enables optimized dissolution rates and reactivity.

Core-Shell Particle Developmente Materials

A critical aspect of modern chemical engineering involves functionalizing powders as core-shell structures with precisely controlled layer thicknesses for enhanced catalytic and reactive properties.

CHOOSE YOUR COMPOSITION

Advanced Powder Solutions for the Chemical Industry

From custom-made powders to advanced nanoparticle production, modern material solutions are unlocking new possibilities in chemical processing, catalysis, and electrochemical applications. With precise control over particle size, morphology, and surface properties, manufacturers can achieve higher efficiency, safety, and product performance.

01

Custom Powder Production Services

AMAZEMET offers the ability to order custom-made powders, including reactive materials, tailored to specific chemical industry needs.

02

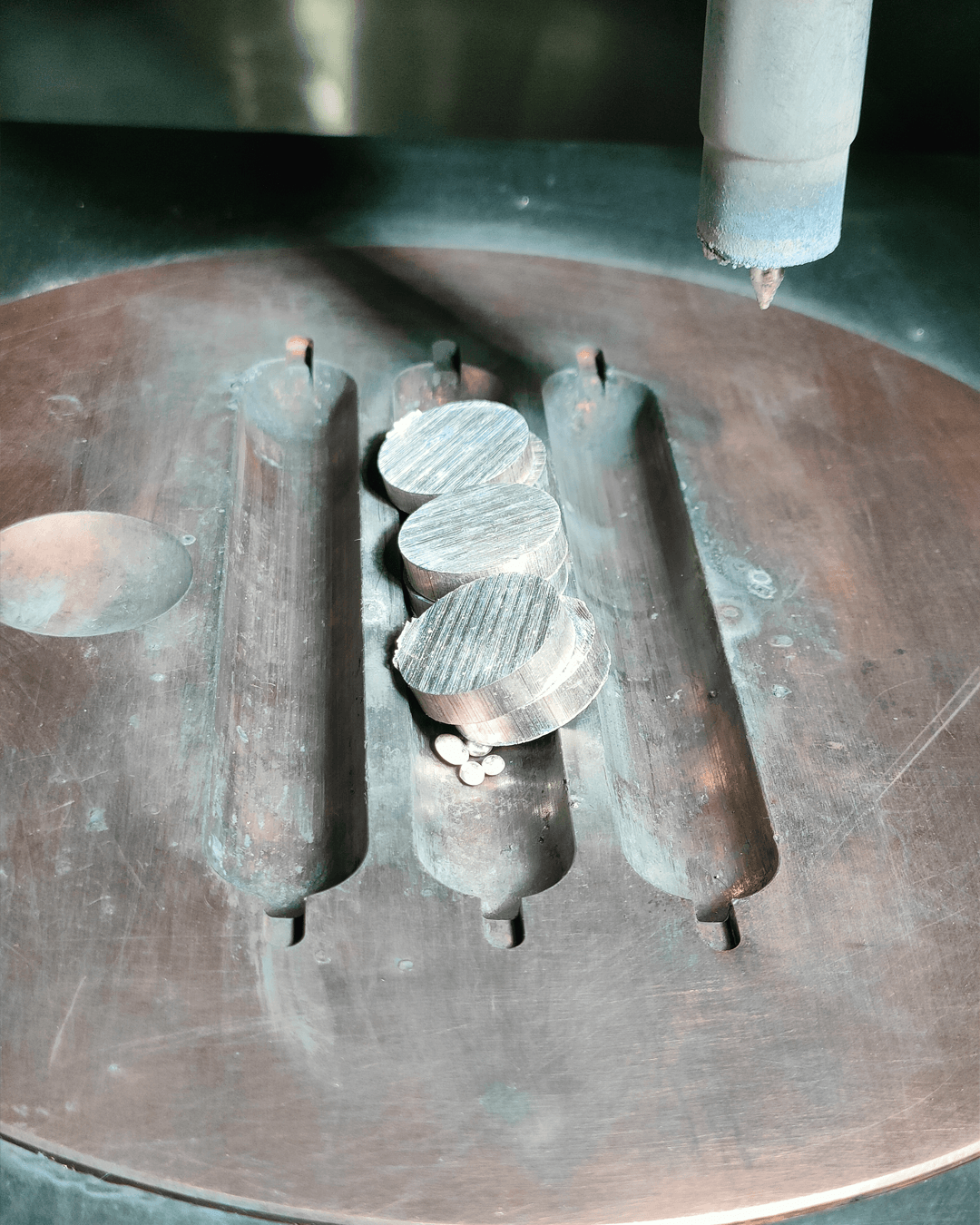

Spherical Powders with Controlled Solubility

Ultrasonic atomization enables the production of powders with uniform particle morphology, allowing for predictable dissolution rates in chemical processes.

03

Controlled-Surface-Area Powders for Catalysis:

Advanced powder manufacturing techniques provide a repeatable and scalable method for producing materials with specific surface areas, improving efficiency in catalytic reactions.

04

Core-Shell Powders for Electrochemical Applications

Using electrochemical deposition techniques, functional coatings with controlled thickness can be applied to spherical powders, enabling advanced applications in catalysis, and material science.

05

Nanoparticles for Advanced Chemical Applications

AMAZEMET utilizes ultrasonic-assisted plasma evaporation to produce high-purity nanoparticles, including silicon, silver, platinum, gold, and iridium. These materials offer unique properties for applications in electronics, catalysis, biomedical research, and high-performance coatings.

06

Custom Powder Production Services

AMAZEMET offers the ability to order custom-made powders, including reactive materials, tailored to specific chemical industry needs.

AMAZEMET

Your Partner in High-Precision Powder Manufacturing

As a leader in advanced material processing, AMAZEMET delivers innovative powder solutions for the chemical industry, offering customized powder synthesis, tailored solubility control, and scalable manufacturing techniques to support industrial and research applications.

Scientific Publications and Industry Collaborations

AMAZEMET actively supports chemical material research, contributing to advancements in controlled solubility powders, catalyst optimization, and functionalized particle engineering:

01

Next-Generation Encapsulation Strategies for High-Efficiency Thermal Storage

Cutting-edge research in encapsulation techniques is overcoming long-standing challenges in metallic PCM stability, paving the way for more efficient, durable, and scalable thermal energy storage solutions.

02

Unlocking New Potentials in Thermal Energy Storage with Electrochemical Encapsulation

Electrochemical deposition is opening new avenues for stabilizing metallic phase change materials, significantly improving their thermal performance and lifecycle in energy storage systems.

WHY AMAZEMET

Customized Powder Solutions for Chemical Applications

Discover how our innovative material solutions can support nuclear research, reactor technology, and isotope production.

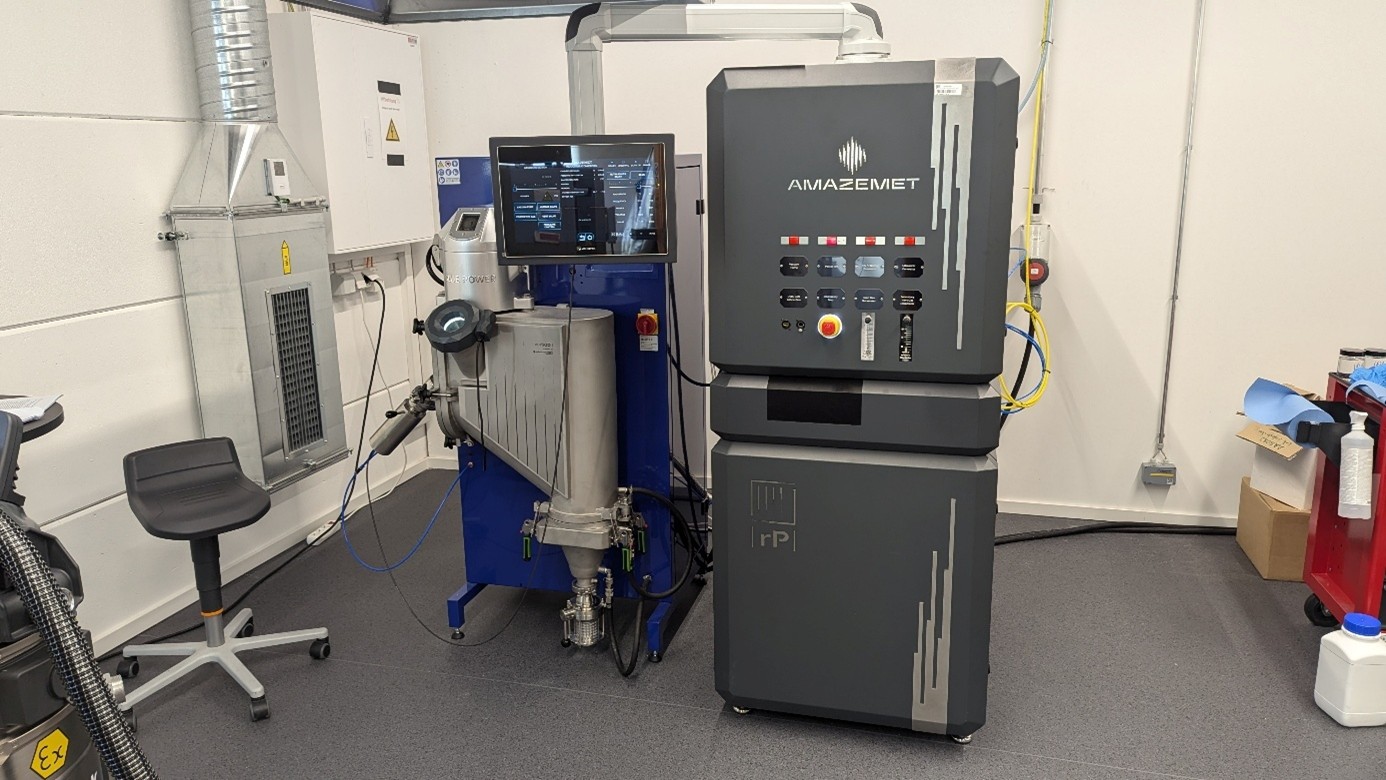

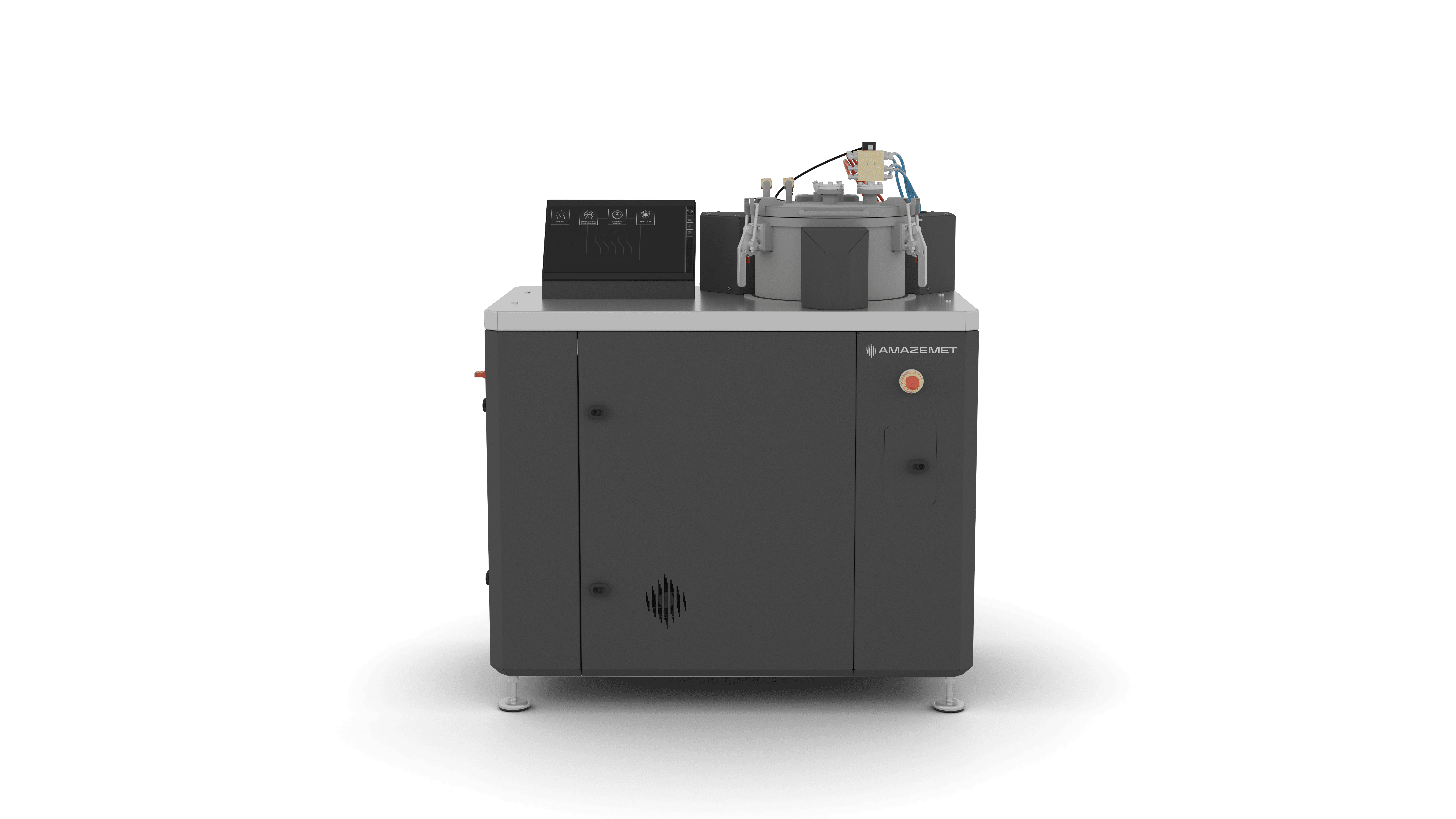

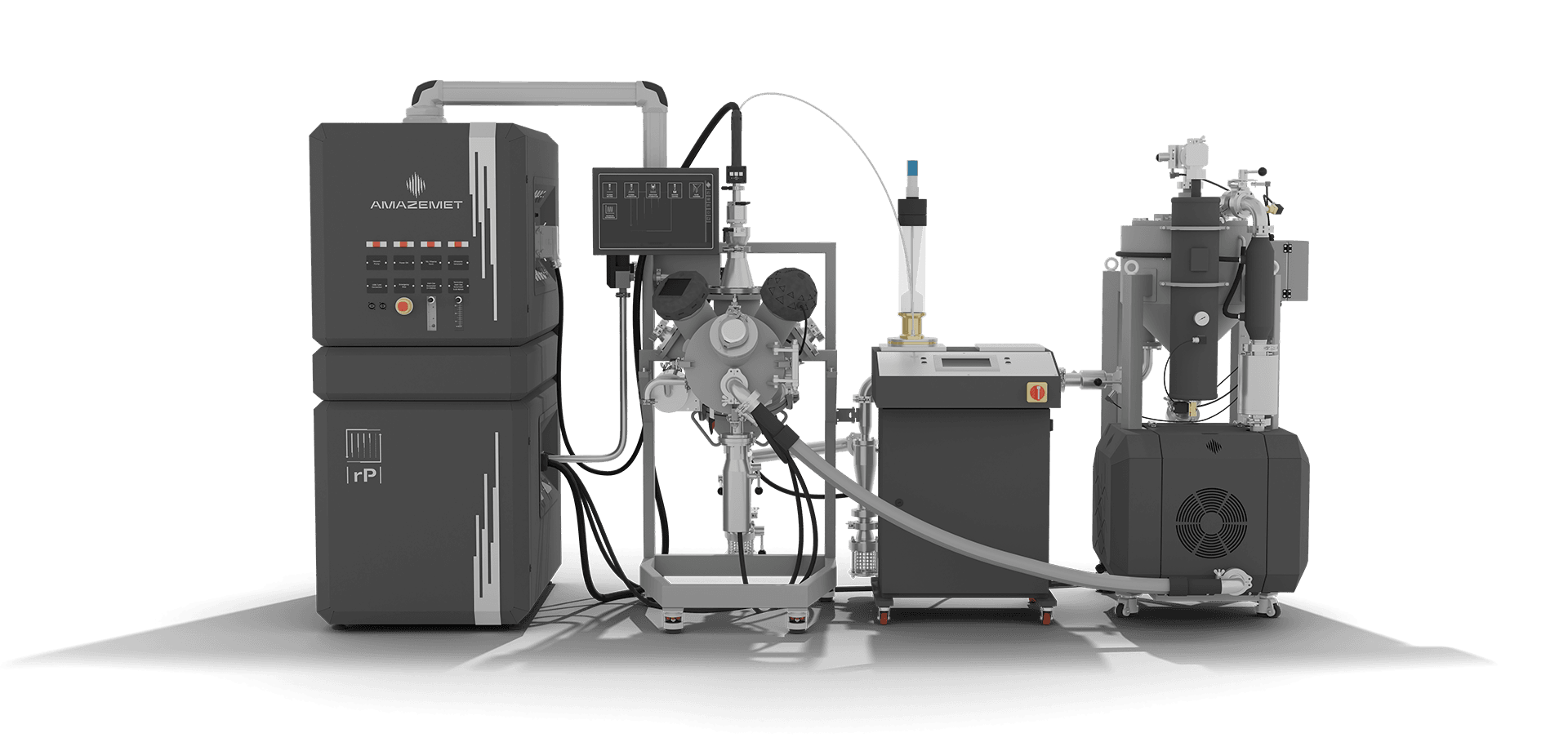

rePOWDER

Ultrasonic atomization system for producing spherical powders with tailored solubility, reactivity, and surface area characteristics.

inFURNER

High-vacuum furnace ensuring precise heat treatment for modifying material properties.

Powder2Powder

High-vacuum furnace ensuring precise heat treatment for modifying material properties.

FREEDOM IN METAL AM

DEVELOPMENT & PRODUCTION

RESEARCH PARTNERSHIP

Drive Chemical Innovation Through Research Collaboration with AMAZEMET

Partner with AMAZEMET to explore cutting-edge material solutions for the chemical industry. From tailored powder synthesis to advanced nanoparticle production, we help accelerate your R&D efforts and bring next-generation materials to life.

ENABLING MATERIALS FOR CUTTING-EDGE APPLICATIONS

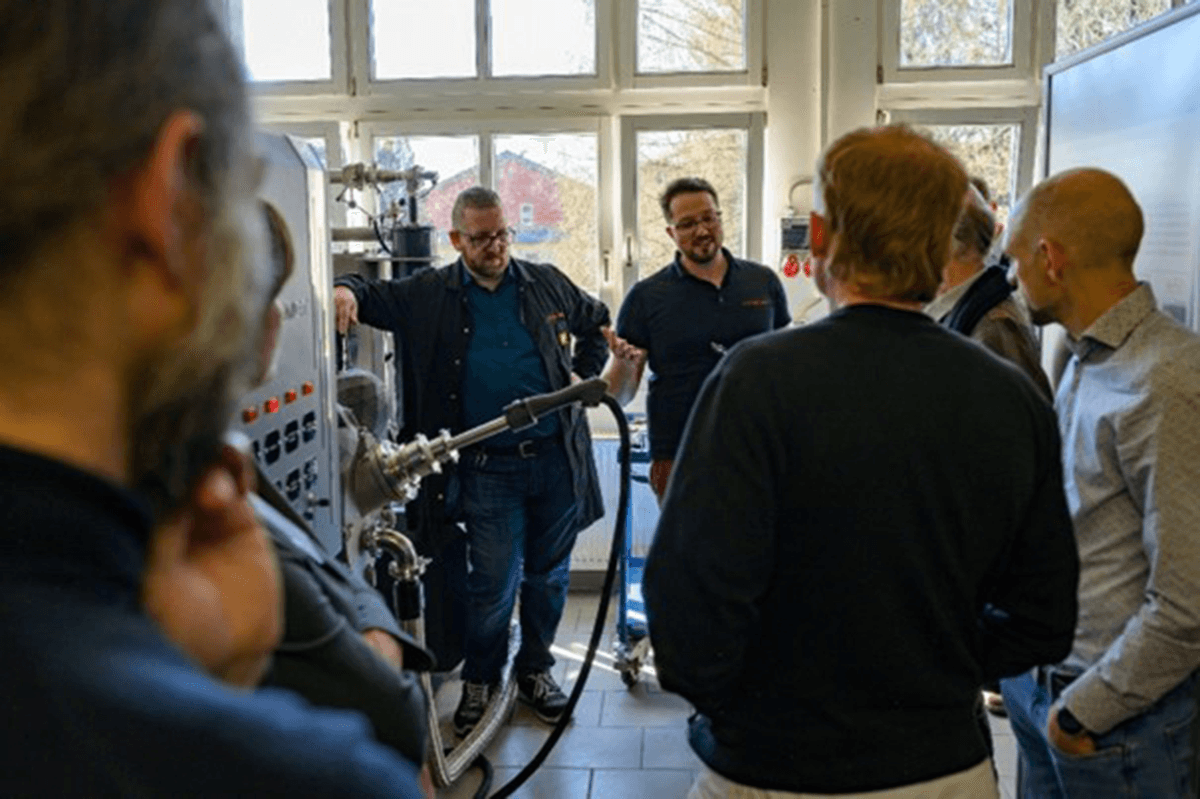

Explore Our Work in Action

Discover how AMAZEMET supports research and innovation through real-world collaborations and deep technical insights

Case Studies

Our case studies showcase how we’ve supported partners across industries with tailored solutions—from alloy development to process optimization. They focus on real challenges and how our technology helped turn ideas into results.

Application Notes

Application notes provide a deeper look into the technical aspects of our systems, methods, and materials. They’re ideal for researchers and engineers seeking detailed knowledge and insights to guide their own experiments and development work.

LET’S TALK

Take Your Chemical Materials to the Next Level with AMAZEMET

Discover how our advanced powder solutions can enhance your chemical processes and material development.

Contact us today to get a quote for your customized rePOWDER setup.