INTRODUCTION

The Role of Metal Powders in Chemical Processes

The Role of Metal Powders in Chemical Processes

Metal powders are essential in a wide range of chemical processes, from catalysis and synthesis to coatings and advanced reactants. Their particle size distribution directly influences flowability, reaction kinetics, and overall efficiency. Whether for industrial-scale chemical production or laboratory research, high-quality metal powders enhance reaction yields, process stability, and cost-effectiveness.

As industries push for more advanced materials, the demand for precisely tailored metal powders continues to grow. Sectors such as energy storage, pharmaceuticals, and electronics increasingly rely on optimized powder characteristics to improve performance, sustainability, and material efficiency. However, obtaining metal powders with consistent properties remains a challenge.

Challenges in Metal Powder Utilization

Despite their importance, metal powders pose several challenges that can hinder their effective use in chemical processes. Addressing these challenges requires innovative atomization and refinement techniques to ensure high purity, controlled particle size, and sustainable powder management.

Inconsistent Particle Size

Many traditional atomization methods yield a broad particle size distribution, leading to inconsistencies in catalytic and chemical performance.

Oxidation & Contamination

Powders produced through conventional milling and atomization processes may suffer from oxidation or contamination, which can alter their chemical properties and require costly purification steps

Complex Alloy Development

Producing novel alloys or multi-element compositions is challenging, as large-scale atomization processes require high material input and specialized feedstocks.

Applications of Metal Powders in Chemical Reactions

Metal powders play a crucial role in accelerating reaction rates and improving efficiency in various chemical processes:

01

Hydrogenation Reactions (Nickel Powder)

Finely dispersed nickel powders serve as effective catalysts in hydrogenation reactions, particularly in the production of hydrogenated oils and synthetic fuels.

02

Ammonia Synthesis (Iron Powder Catalysts)

The Haber-Bosch process relies on iron-based catalysts to convert nitrogen and hydrogen into ammonia, a key ingredient in fertilizers and industrial chemicals.

03

Environmental Catalysis (Platinum Powder)

Platinum nanopowders are widely used in catalytic converters, facilitating the oxidation of carbon monoxide (CO) into carbon dioxide (CO₂), reducing vehicle emissions and industrial pollution.

Advancing Metal Powder Processing

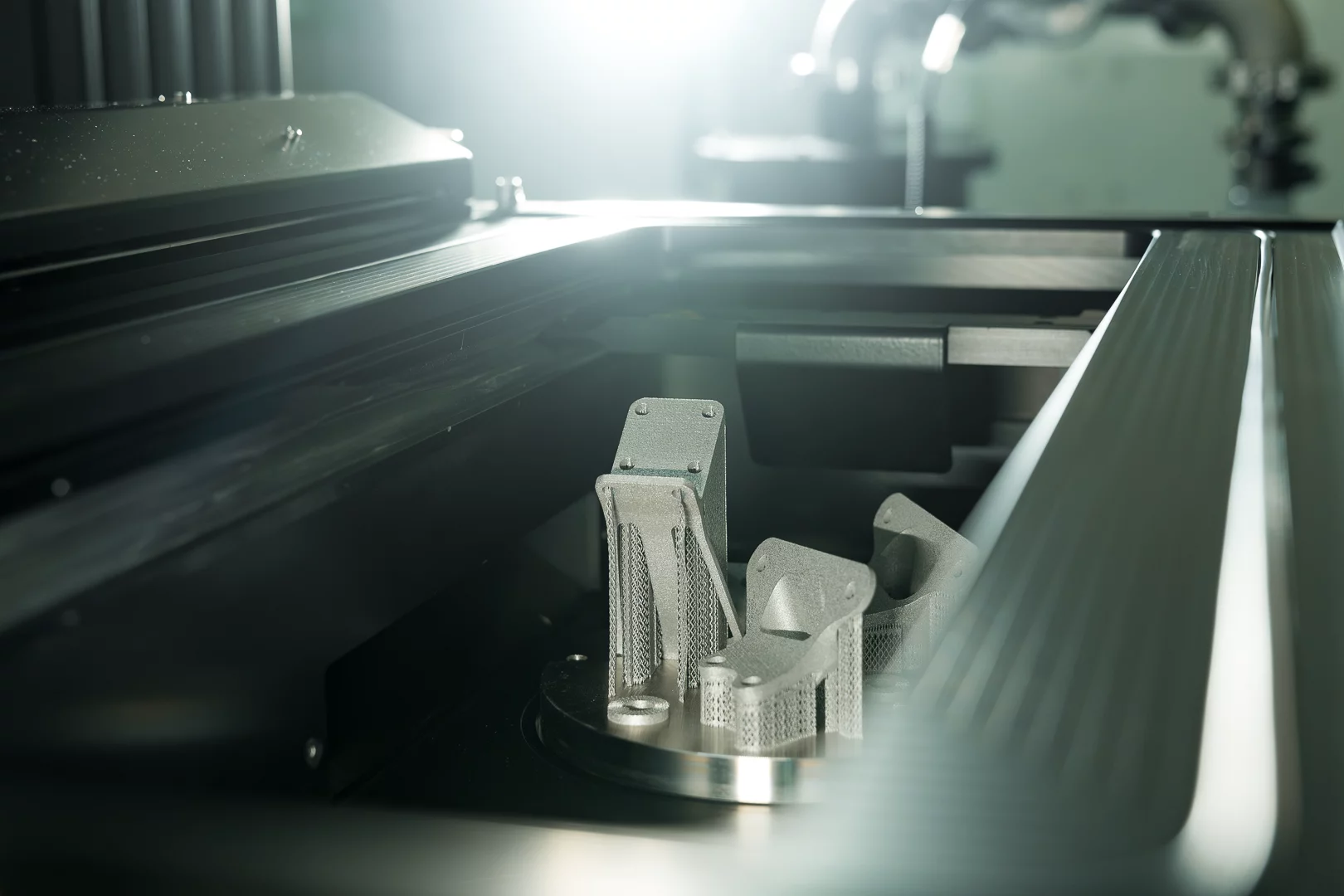

Tailored Metal Powder Atomization Services

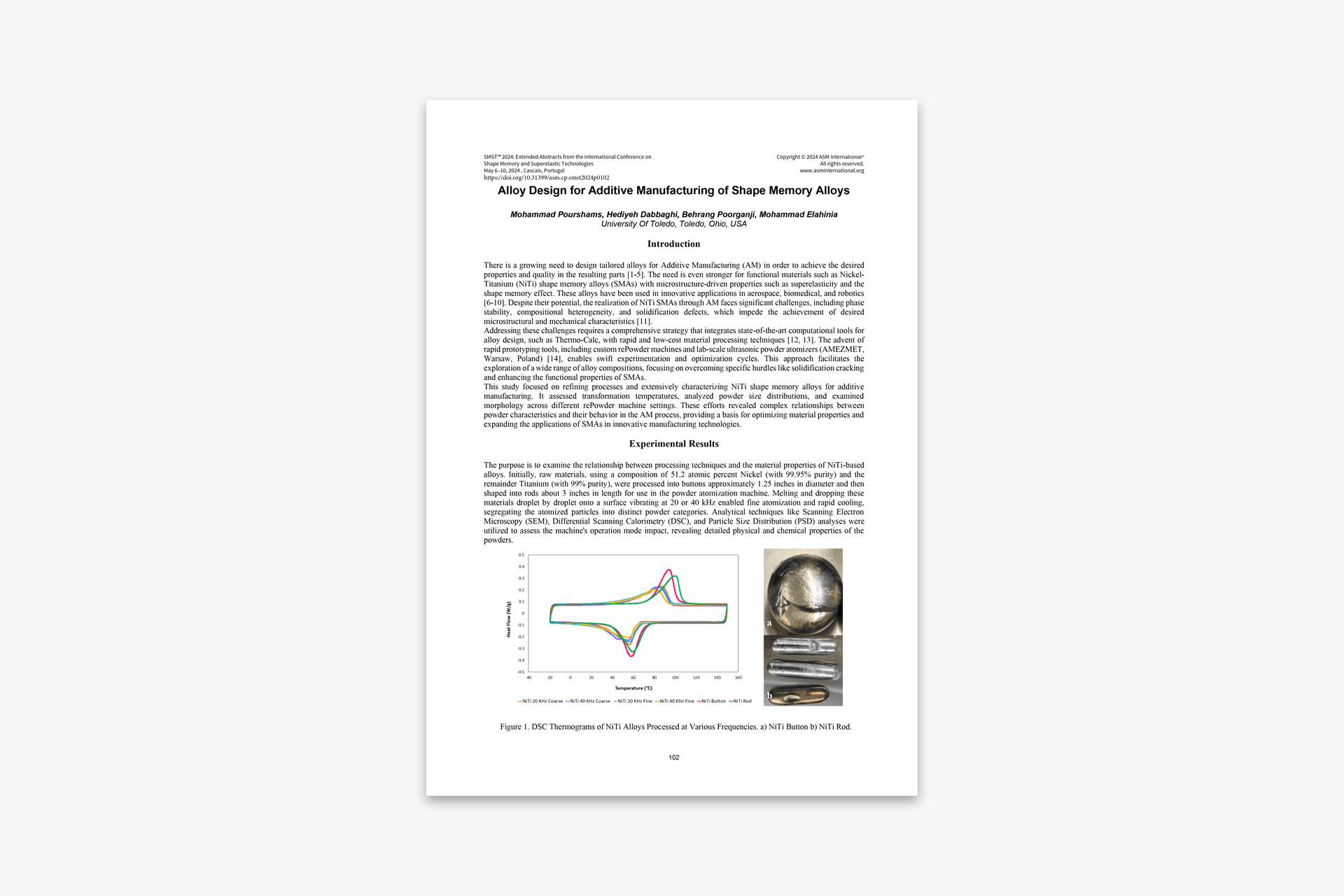

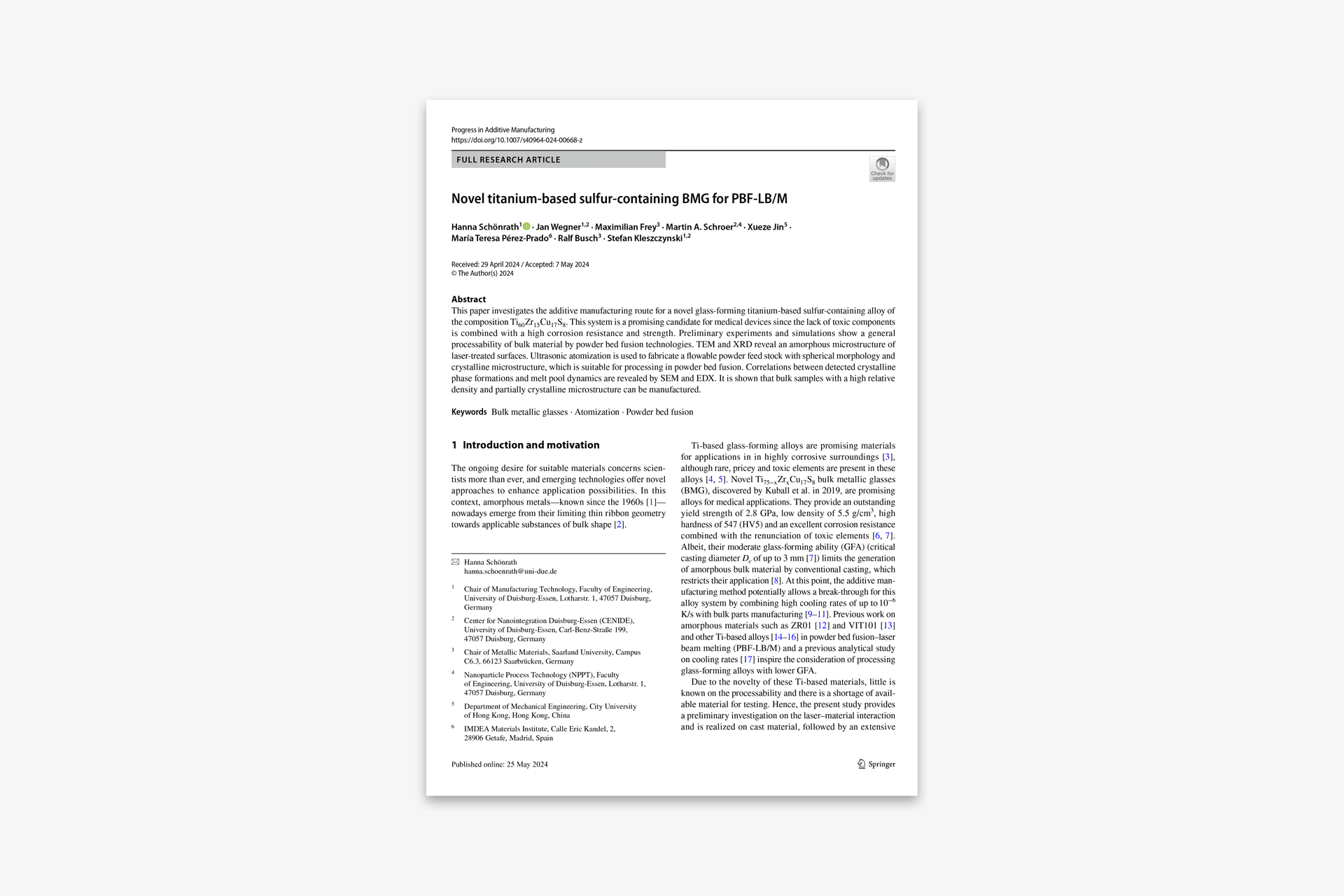

AMAZEMET specializes in ultrasonic metal powder atomization services, supporting research, prototyping, and industrial-scale applications. Our team consists of PhD holders, PhD candidates, and expert engineers actively engaged in European research projects and contributing to scientific advancements in materials science. We collaborate with leading institutions, participate in high-impact EU-funded initiatives, and publish peer-reviewed studies on metal powder applications and atomization techniques. This expertise allows us to provide cutting -edge solutions for researchers and industry professionals seeking high-quality, customized powders for their chemical and manufacturing needs.

Why Choose AMAZEMET?

By utilizing AMAZEMET atomization service, you gain access to high-quality, application-specific metal powders without the need for in-house atomization equipment. Whether for catalyst development, material refinement, or powder reprocessing, AMAZEMET provides the expertise to support your research and industrial applications.

Tailored Powder Production

We develop powders optimized for specific research needs.

High-Purity Metal Powders

Our advanced atomization processes ensure minimal contamination and uniform properties.

Flexible Small-Batch Production

Ideal for researchers and manufacturers who need customized, limited-quantity powders.

Sustainability & Cost Savings

Our reconditioning services extend the usability of powders, reducing material waste.

OUR CUSTOMERS

Trusted by Innovators Worldwide

AMAZEMET is proud to collaborate with a diverse range of clients who trust our cutting-edge solutions to advance their projects. rePOWDER is currently being used to atomize novel powder compositions in: