INTRODUCTION

Electron Beam Melting

Electron Beam Melting

Electron Beam Melting (EBM) is an advanced additive manufacturing (3D printing) technology that uses a high-powered electron beam to build dense, high-performance metal components. Developed in the late 1990s and commercialized primarily by Arcam (now part of Colibrium Additive), EBM has found widespread adoption in aerospace, medical, and industrial applications. Other system manufacturers include Freemelt (for R&D), JEOL, ProBeam, and Wayland Additive. Operating in a high-vacuum environment significantly reduces oxidation and contamination during processing, making EBM particularly suitable for reactive metals like titanium alloys and for high-temperature materials such as nickel-based superalloys or Titanium-Aluminides. Elevated build temperatures further help alleviate residual stress and facilitate efficient powder reuse, distinguishing EBM from laser-based methods. Combined, these factors allow for the production of complex geometries with exceptional mechanical properties, positioning EBM as a premier choice for demanding applications.

How the EBM process works

The EBM process starts by distributing a thin layer of metal powder onto the build platform using a recoater. Guided by electromagnetic coils, the electron beam preheats the powder bed to mitigate electrostatic charging—often referred to as the ‘smoking’ effect. After preheating, the beam selectively melts areas of the powder according to the CAD-defined geometry, consolidating each layer sequentially.

A core advantage of EBM is its robust thermal management: by maintaining an elevated build temperature, the process minimizes thermal gradients, thereby reducing residual stresses and preventing part distortion. All of this occurs under vacuum conditions, which prevent oxidation and enable high powder recyclability. Key hardware components include the electron gun, electromagnetic beam control system, vacuum chamber, and powder handling mechanisms, all working in synergy to ensure a stable and precise build.

EBM TECHNOLOGY

Challenges of EBM technology

Despite its advantages, EBM has several challenges that can limit its widespread adoption:

- Lower resolution and surface roughness: Compared to LPBF, EBM-printed parts have a rougher surface finish, often requiring post-processing.

- Material limitations: While excellent for titanium and nickel-based superalloys, the range of processable materials is narrower than LPBF. The technology is less popular compared to LPBF, resulting in fewer commercially available dedicated materials.

- High equipment and operational costs: The vacuum chamber and electron beam technology contribute to high initial investment and maintenance costs.

- Powder bed charging: Using an electron beam can cause electrostatic charging of the powder bed, leading to uneven layer distribution. This phenomenon occurs due to the interaction between the high-energy electron beam and fine metallic powders, which can create localized electric fields. These fields may cause powder particles to repel each other, a phenomenon known as the ‘smoking effect’, resulting in inconsistent layer deposition and potential defects in the final part.

- Need for specialized personnel: EBM technology requires experienced technicians and skilled application engineers to ensure successful manufacturing, as process parameters, heat management, and part orientation significantly impact final quality.

EBM

Capabilities of EBM

Capabilities of EBM

EBM enables the production of complex, high-strength parts with superior mechanical properties compared to traditional manufacturing methods. Due to high processing temperatures and vacuum environment, the process is well-suited for reactive and high melting point alloys, titanium alloys (e.g., Ti-6Al-4V) and nickel-based superalloys, Titanium-Aluminides, and refractory materials such as Tungsten or C103 Niobium alloy. Some of the key capabilities of EBM include:

High-temperature operation

Enables processing of materials that are challenging for LPBF, such as refractory materials that can be difficult to process due to their high melting points or materials that crack under high cooling rates, such as Titanium-Aluminides, or Tool Steels.

Low residual stresses

Preheating and gradual cooling of the powder bed reduce thermal stresses, minimizing the risk of cracking or distortion. Unlike LPBF, EBM typically does not require additional heat treatment, as the high processing temperatures and controlled cooling environment effectively relieve residual stresses during the build process.

Higher build rates

EBM can achieve faster production times than LPBF due to its ability to simultaneously melt larger areas. The electron beam, controlled by electromagnetic coils, can move at speeds in the km/s range due to the absence of moving mechanical parts. This enables EBM to maintain multiple melt pools at the same time and execute advanced scanning strategies such as point or pixel melting, further enhancing process efficiency and build rates.

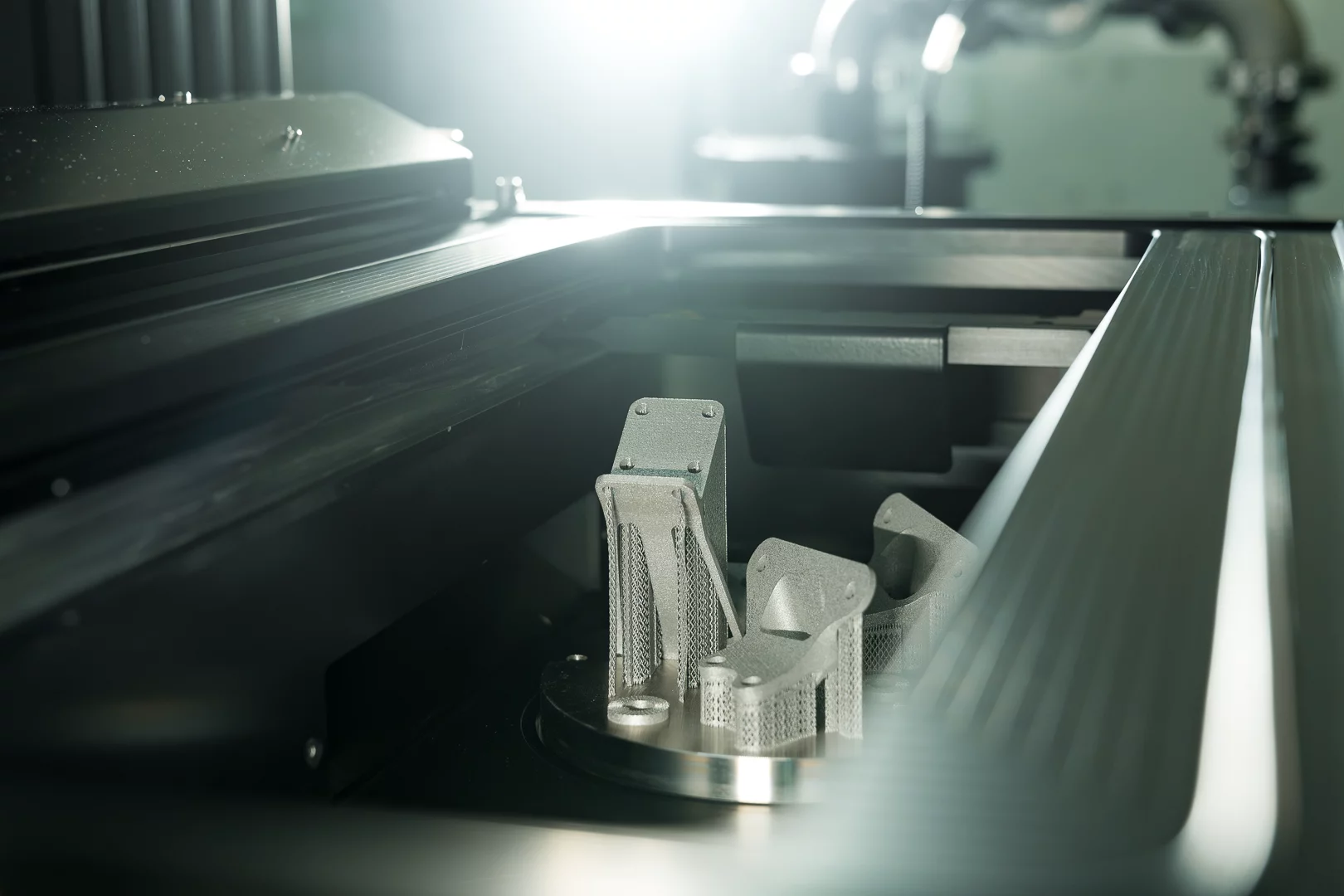

Support structures as heat exchangers

Unlike in LPBF, support structures in EBM primarily function as heat exchangers, helping to dissipate heat efficiently during the build process. This unique characteristic allows for vertical part stacking, significantly increasing production capabilities within a single build cycle. Additionally, support-free printing is possible in some instances, depending on part geometry and heat management strategies.

METAL POWDERS

Powder requriments for EBM

The quality of the powder used in EBM significantly impacts the final part properties and overall process efficiency. However, EBM is generally less sensitive to powder quality compared to LPBF due to the deeper interaction of the electron beam with the material. This deeper penetration allows EBM to handle powders with minor surface oxidation or imperfections more effectively than LPBF, where oxygen films on powder particles can significantly impact the melting process. Additionally, since EBM operates in a vacuum, oxidation during printing is minimized, further reducing the impact of powder degradation over multiple build cycles. EBM powders must meet strict criteria to ensure optimal performance, including high sphericity for improved flowability and packing density, a controlled particle size distribution typically in the 45-105 µm range to ensure consistent melting, and low oxygen and moisture content to prevent brittleness and degradation. Since EBM operates in a vacuum, the powder must also be free of volatile contaminants that could compromise the process. Moreover, EBM has a high powder recycling rate due to its vacuum environment, requiring powders to maintain their properties over multiple build cycles.

What Limits the Development of Novel Alloys?

High Operational Costs of Gas Atomization

Gas atomization remains the primary technology for producing metal powders for AM processes and large-scale manufacturing. However, it requires large volumes of expensive inert gases like argon, nitrogen, or helium, significantly increasing operational costs. The systems also operate at extremely high pressures—up to 50 bar (5 MPa) or more—which further drives infrastructure expenses.

Limited Accessibility for Research and Small-Scale Development

Operating gas atomization equipment requires specialized staff and industrial facilities, making it impractical for most research labs. Additionally, significant feedstock quantities are needed for efficient operation, limiting the flexibility needed for small-batch or experimental alloy development.

Inefficient Powder Size Control and Material Waste

Gas atomization offers limited control over powder size distribution. Typically, only 40-60% of the produced powder meets the requirements for EBM, resulting in high material waste and reduced process efficiency.

Limitations of Alternative Powder Production Methods

Other spherical powder production technologies, such as plasma spheroidization and centrifugal atomization (Plasma Rotating Electrode Process – PREP), also face limitations. They require specific feedstock forms and large-scale industrial setups, making them better suited for production rather than flexible R&D environments.

Challenges with Reactive and Specialized Materials

Reactive materials like titanium and nickel-based superalloys require specialized feedstock preparation methods. These include:

- Electrode Induction Gas Atomization (EIGA) for rods

- Plasma Atomization for wires

Both add significant costs and logistical challenges, making them less practical for novel alloy development.

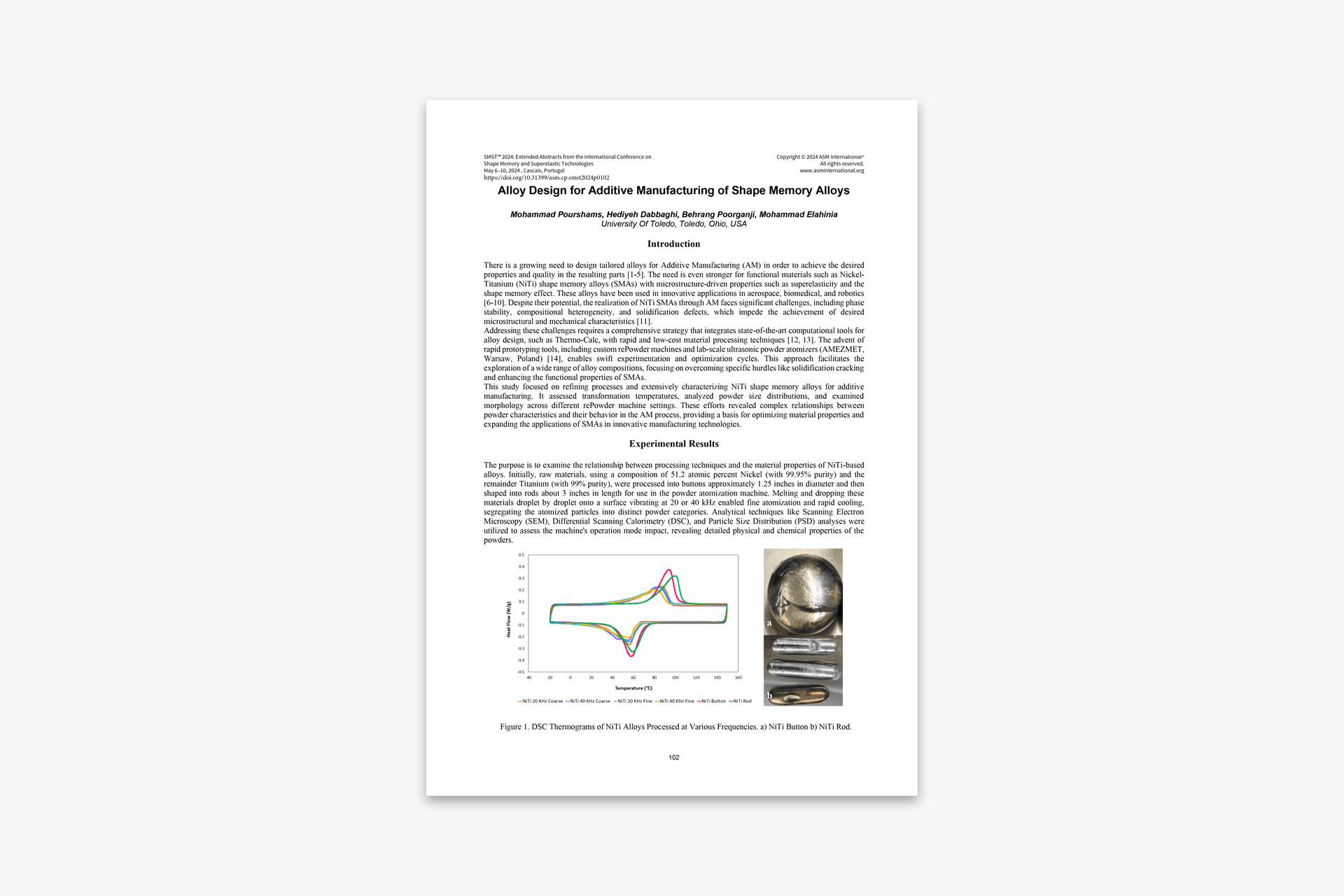

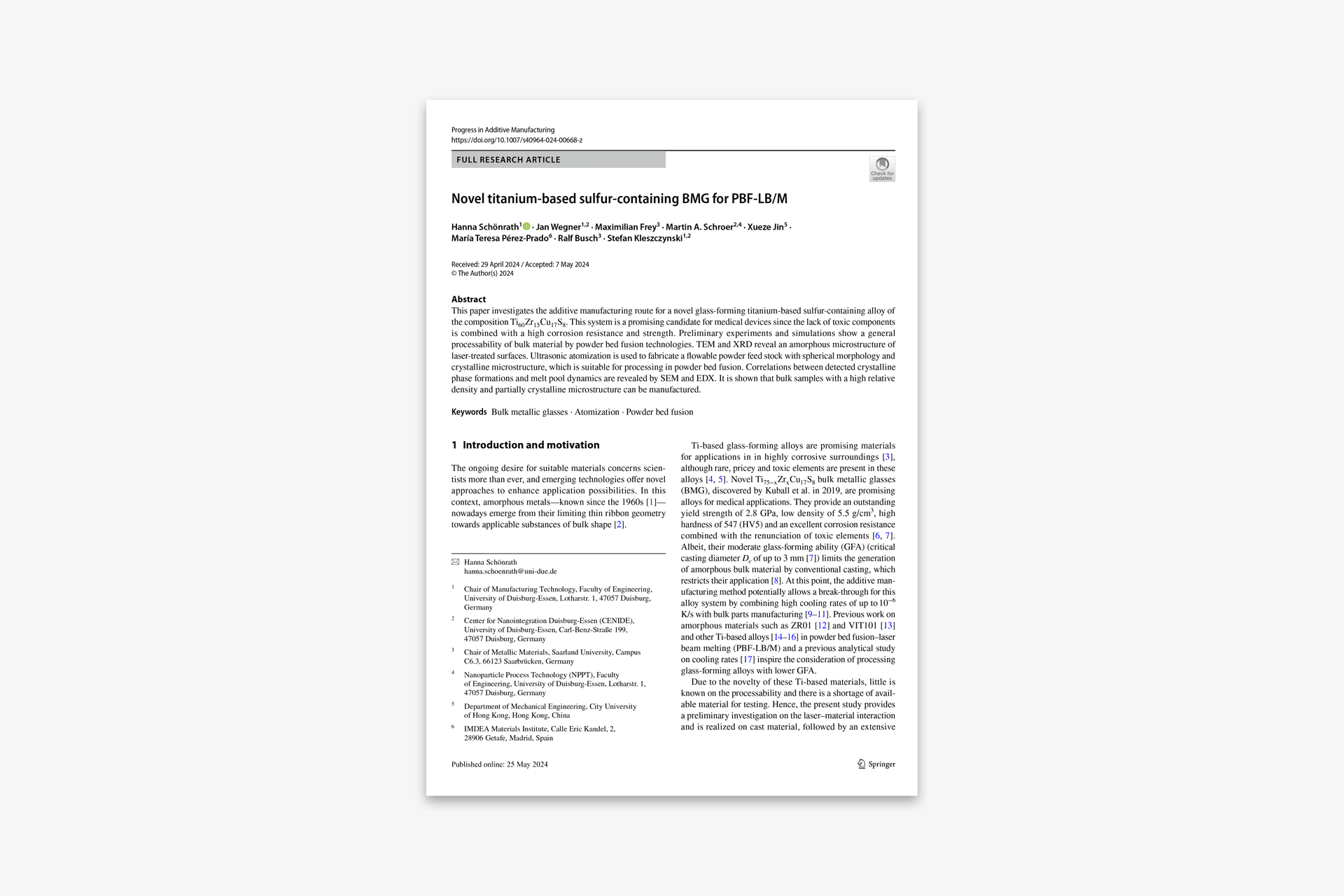

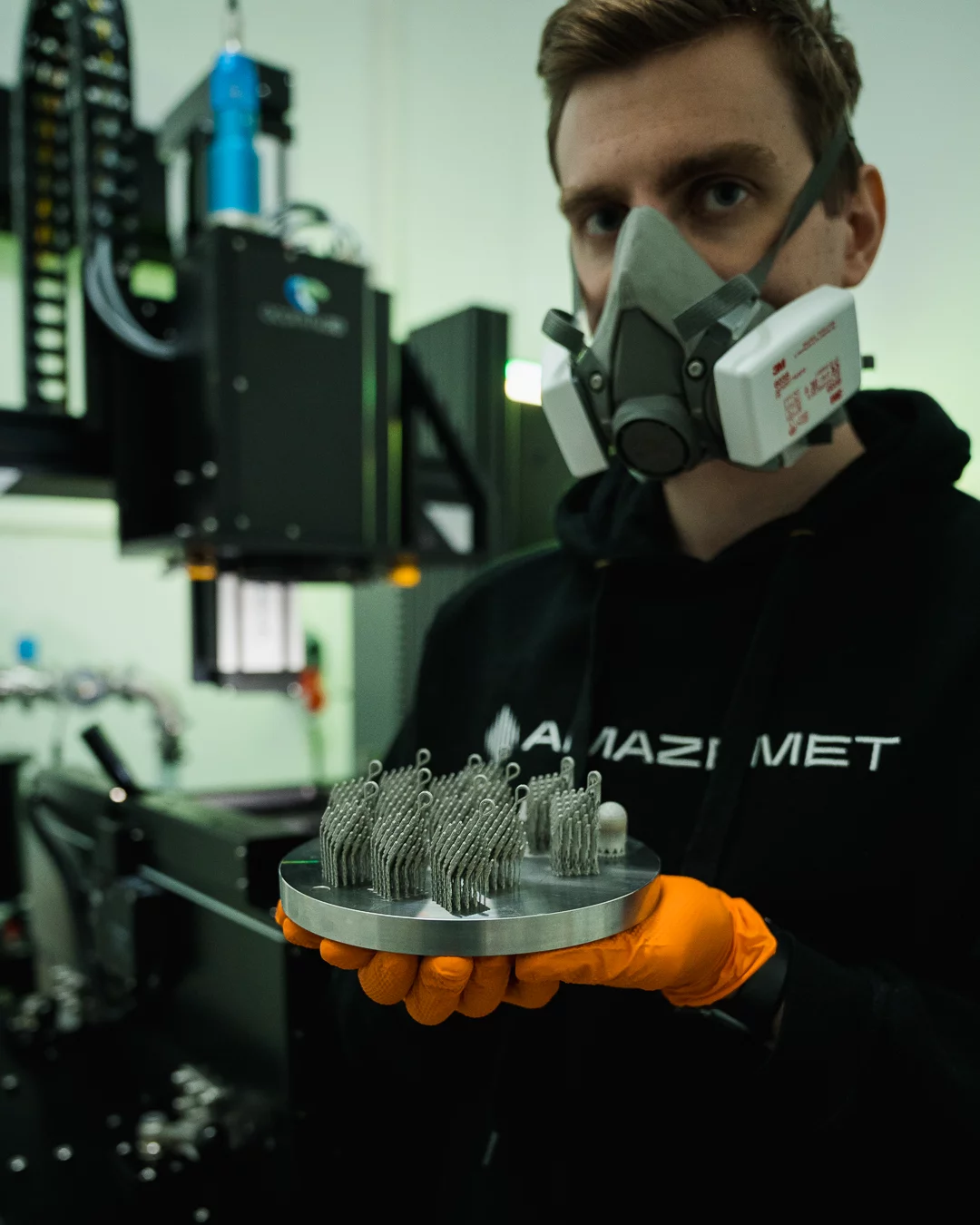

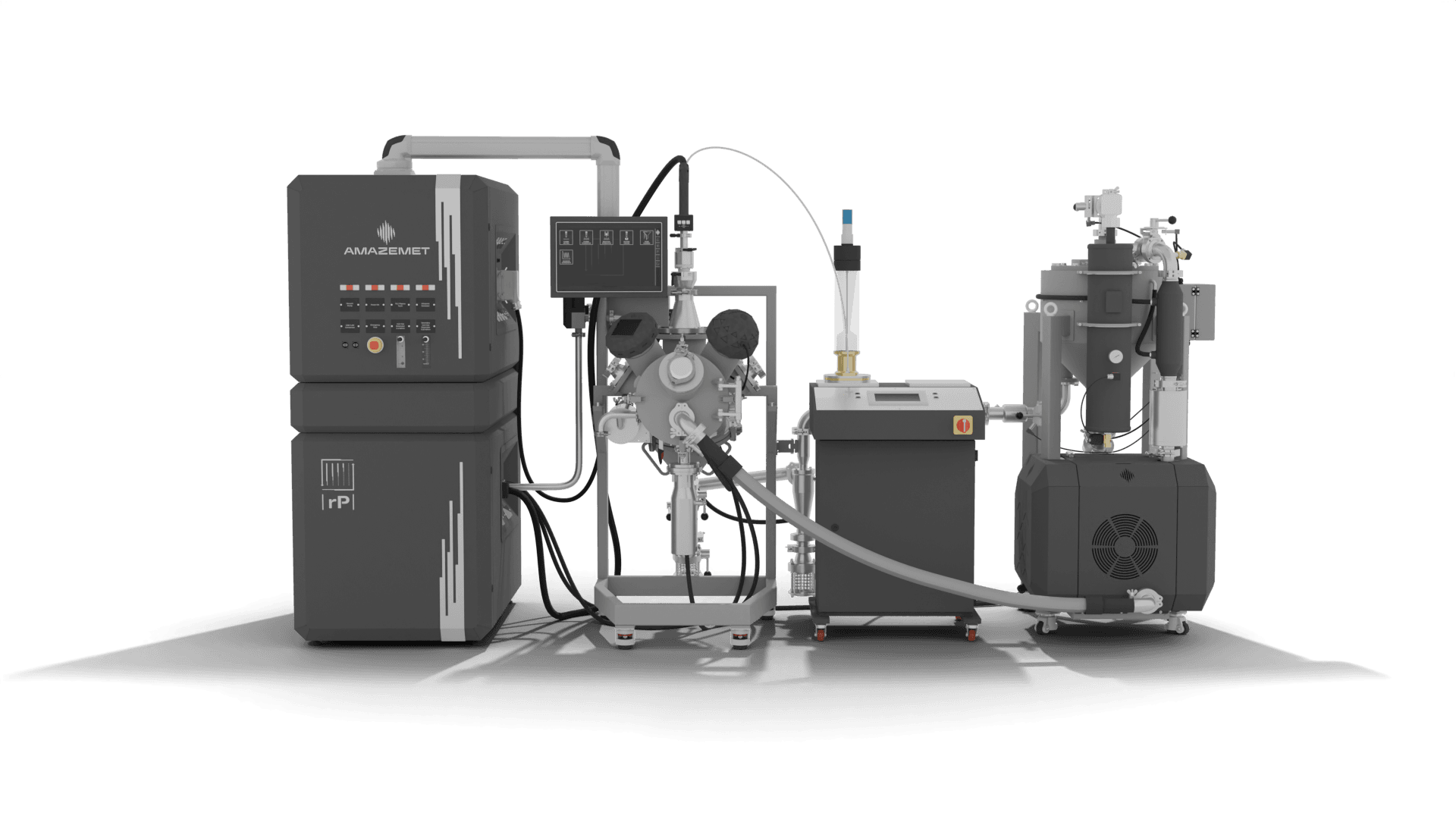

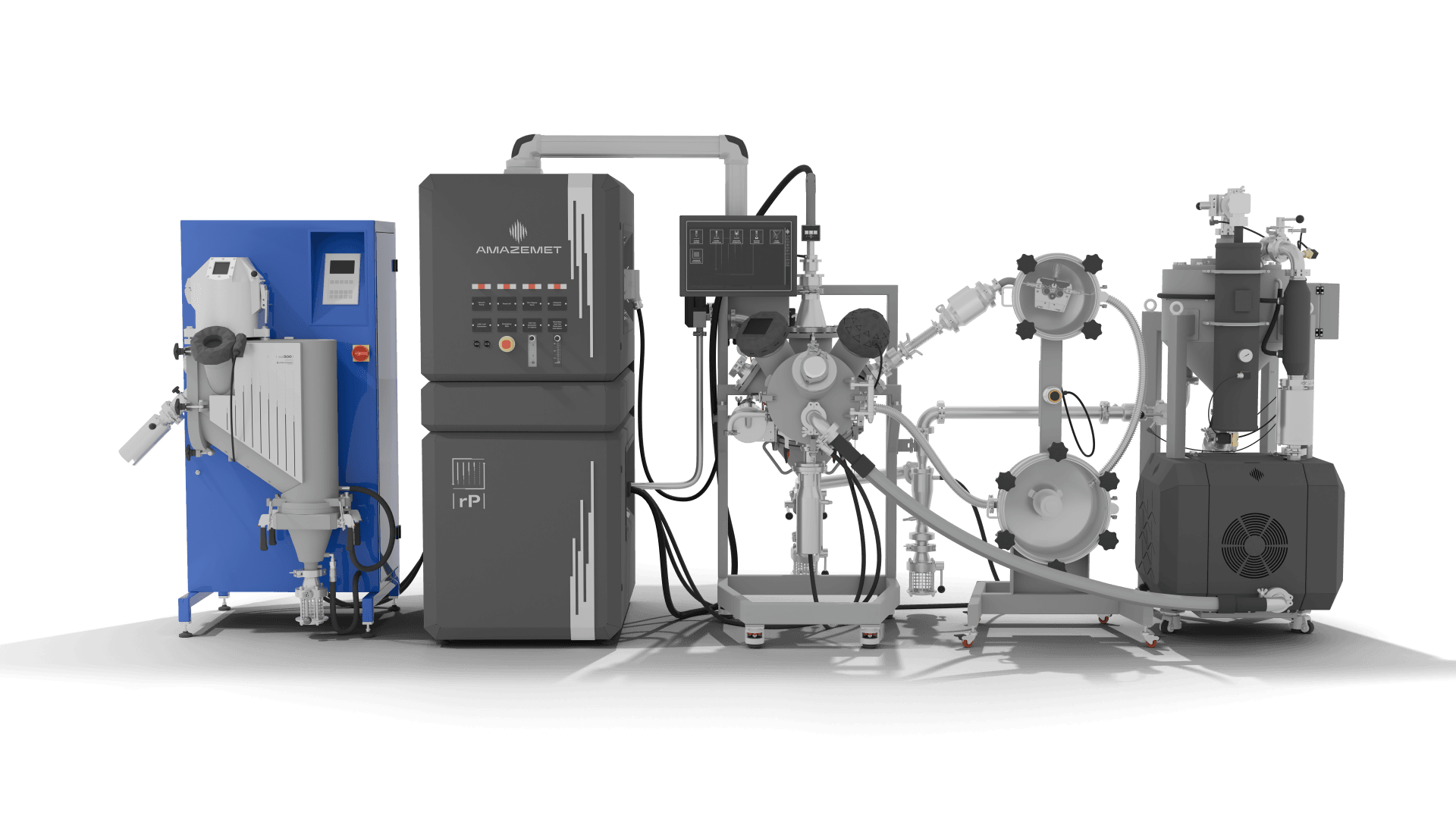

Ultrasonic atomization for novel EBM alloys

AMAZEMET developed a lab-scale atomizer—rePOWDER—based on ultrasonic atomization technology, specifically designed for developing novel alloys for Electron Beam Melting. It overcomes the challenges associated with gas atomization technology. By employing high-frequency ultrasonic vibrations to break molten metal into microdroplets, rePOWDER enables precise control over droplet formation, resulting in uniform, high-quality feedstock with minimal oxygen pickup—a critical parameter for EBM.

Notably, up to 90% of the atomized powder meets the size requirements for EBM, significantly reducing waste compared to gas atomization methods and enhancing the efficiency of material utilization. Consequently, rePOWDER provides a highly efficient platform for developing novel materials tailored to the stringent demands of Electron Beam Melting, driving innovation across aerospace, biomedical, and energy sectors.

A common sustainability misconception

You will often hear from AM evangelists claim that ‘only the volume of powder corresponding to the final part geometry is consumed.’ However, in EBM, significant quantities of powder remain within the system throughout multiple build cycles and can degrade due to oxidation, sintering, and agglomeration. The unique challenge in EBM is the formation of a sintered powder cake around the printed components, which requires careful management to ensure powder reusability. While EBM benefits from a vacuum environment that reduces oxidation, the high temperatures involved lead to sintering of surrounding powders, making their direct reuse difficult without proper reconditioning. Monitoring powder quality and effectively recycling partially degraded feedstock is neither straightforward nor always cost-effective, as it requires stringent testing and re-processing to maintain material consistency and part reliability. This highlights the importance of optimized powder handling strategies and efficient recycling techniques to minimize waste and sustain the economic viability of EBM production.

OUR CUSTOMERS

Trusted by Innovators Worldwide

AMAZEMET is proud to collaborate with a diverse range of clients who trust our cutting-edge solutions to advance their projects. rePOWDER is currently being used to atomize novel powder compositions in:

POWDER2POWDER

Making EBM more sustainable

Powder2Powder (P2P) technology directly addresses the sustainability challenges in Electron Beam Melting by enabling a closed-loop production chain where powders can be reused multiple times until they are fully consumed.

Powder2Powder Technology

Unlike conventional powder recycling approaches, which struggle with sintered or partially fused powders, P2P effectively recycles the EBM powder cake. It transforms sintered or irregular particles into highly spherical, satellite-free powders suitable for reuse. The material is fully remelted and homogenized by integrating plasma processing, while ultrasonic atomization ensures uniform droplet formation, leading to consistent powder morphology and quality.

This approach significantly reduces waste and material costs while enhancing process efficiency—allowing manufacturers to ‘buy powder once’ and sustain its usability through multiple build cycles. Unlike conventional plasma spheroidization, P2P ensures that final particle size is independent of the initial feedstock morphology, making it an ideal solution for directly atomizing pulverized or sintered titanium alloys used in EBM. Additionally, it can process blended elemental powders to create pre-alloyed materials with precise chemical compositions. By integrating Powder2Powder technology into their workflow, EBM users gain a sustainable and cost-effective method to maintain a consistent, high-quality powder supply, improving economic and environmental viability.

Ready to Optimize Your EBM Process?

Contact Our Experts: Discuss how AMAZEMET can help you develop novel alloys, obtain high-purity EBM powders, or enhance your additive manufacturing workflow.

01

Let’s talk about closing the loop in your manufacturing process with our metal research multitool – rePOWDER.

02

Let’s develop the perfect powder for your EBM process – reach out to our experts, by request a quote for your powder requirements.