Freedom in Metal AM Develompent & Production

Unlock the new materials and alloys for jewelery

Jewelry design has always been at the intersection of craftsmanship and material innovation. Today, technological advancements enable the creation of high-performance precious metal alloys with enhanced durability, brilliance, and workability. New materials obtained via rePOWDER ultrasonic atomizer by AMAZEMET and processing techniques unlock unprecedented possibilities for jewelers, like products made out from gold, platinum, iridium, and tantalum.

ADDITIVE MANUFACTURING

Challenges in processing of precious metals

Challenges in processing of precious metals

The jewelry industry is built on tradition, artistry, and precision. However, modern manufacturing challenges persist, particularly in the production of custom high-quality products and advanced alloys, especially in the form of metal powder. Conventional methods of material processing often limit design freedom, and increase waste. Additionally, the need for high-purity precious metal alloys based on customer requirements and sustainable production methods creates an increasing demand for innovative solutions.

The jewelry industry is built on tradition, artistry, and precision. However, modern manufacturing challenges persist, particularly in the production of custom high-quality products and advanced alloys, especially in the form of metal powder. Conventional methods of material processing often limit design freedom, and increase waste. Additionally, the need for high-purity precious metal alloys based on customer requirements and sustainable production methods creates an increasing demand for innovative solutions.

Material Limitations

Traditional manufacturing techniques restrict the development of novel alloys with improved wear resistance, luster, and strength. Additionally the materials with low ductility does not find applications.

Production Waste

Precious metal loss during casting, machining, and polishing contributes to high production costs and inefficiencies.

CHOOSE YOUR COMPOSITION

Eye-catching solutions

Discover sustainable, durable, and vibrant jewelry solutions through advanced recycling and innovative alloying techniques.

01

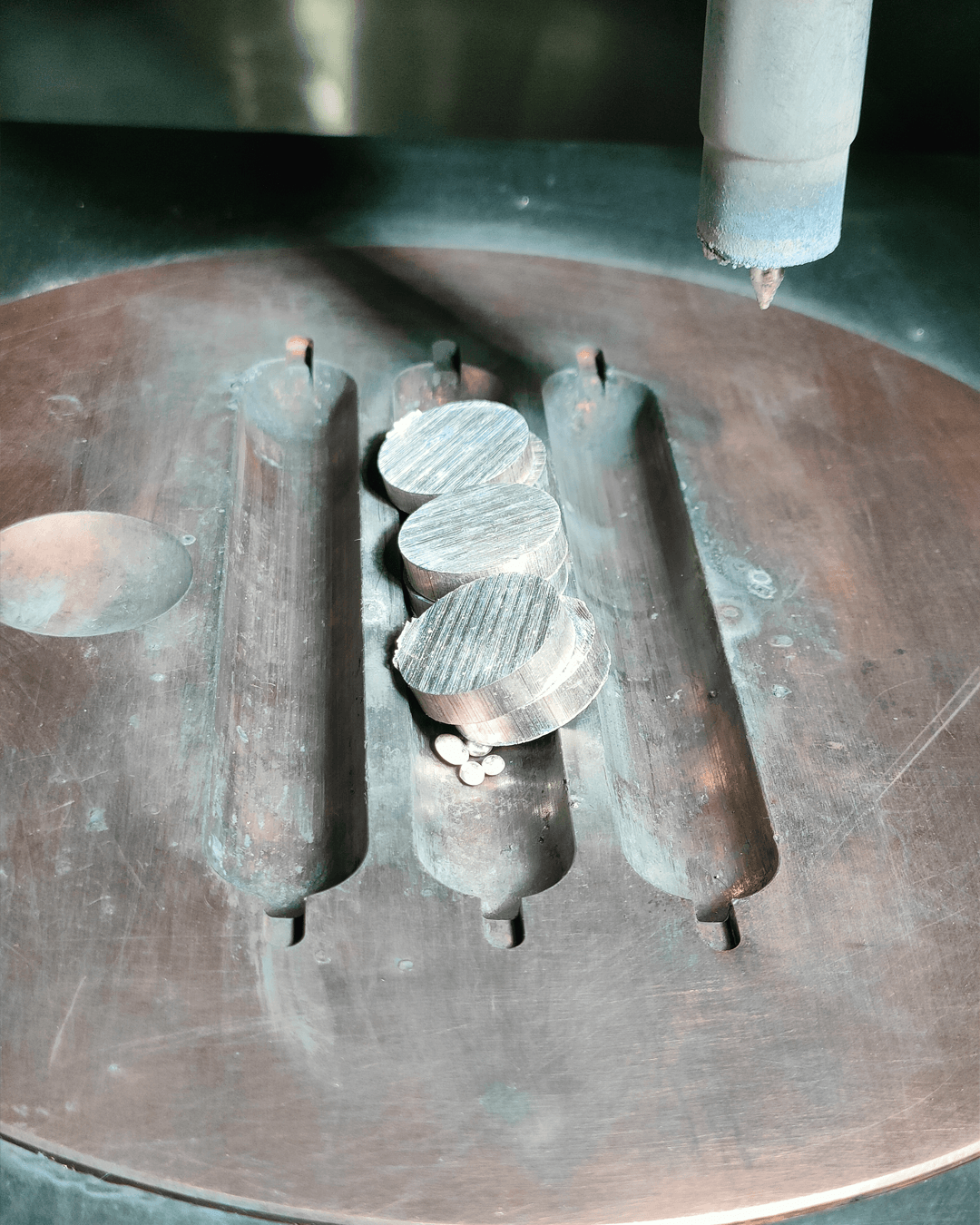

Recycling Jewelry Waste

The jewelry industry generates significant metal waste during casting, machining, and polishing. Implementing advanced recycling techniques allows for the recovery and reuse of these materials without compromising their purity or mechanical properties. Innovative processes such as ultrasonic reatomization enable the transformation of out-of-spec or excess material back into usable powder, reducing material losses and improving cost efficiency.

02

Enhancing Gold Alloys for Durability

Traditional gold jewelry is prone to wear and deformation over time. By carefully alloying gold with elements such as titanium, palladium, or platinum, manufacturers can significantly improve its hardness, scratch resistance, and overall longevity. Controlled alloy development allows for the retention of gold’s aesthetic appeal while enhancing its mechanical properties, making it more suitable for everyday wear.

03

Anodized Niobium and Tantalum for Unique Jewelry Designs

Niobium and tantalum offer an exceptional ability to form stable, colored oxide layers through anodization. This process allows jewelers to create vibrant, corrosion-resistant surfaces without the need for dyes or coatings. By applying precise voltage control during anodization, a wide range of colors can be achieved, expanding creative possibilities in modern jewelry design.

AMAZEMET

Precious metals R&D with Amazemet

AMAZEMET is a company in the additive manufacturing industry, specializing in advanced material solutions and innovative technologies. As a spin-off from the Warsaw University of Technology, AMAZEMET leverages cutting-edge research and engineering expertise to deliver groundbreaking solutions like rePOWDER, inFURNER, and Powder2Powder, which address the most pressing challenges in alloy development, heat treatment, powder production and recycling. With a focus on sustainability, precision, and efficiency, AMAZEMET has become a trusted partner for industry and academia.

WHY AMAZEMET

Solutions for Jewelry Industry

AMAZEMET provides three key solutions tailored to the jewelry industry:

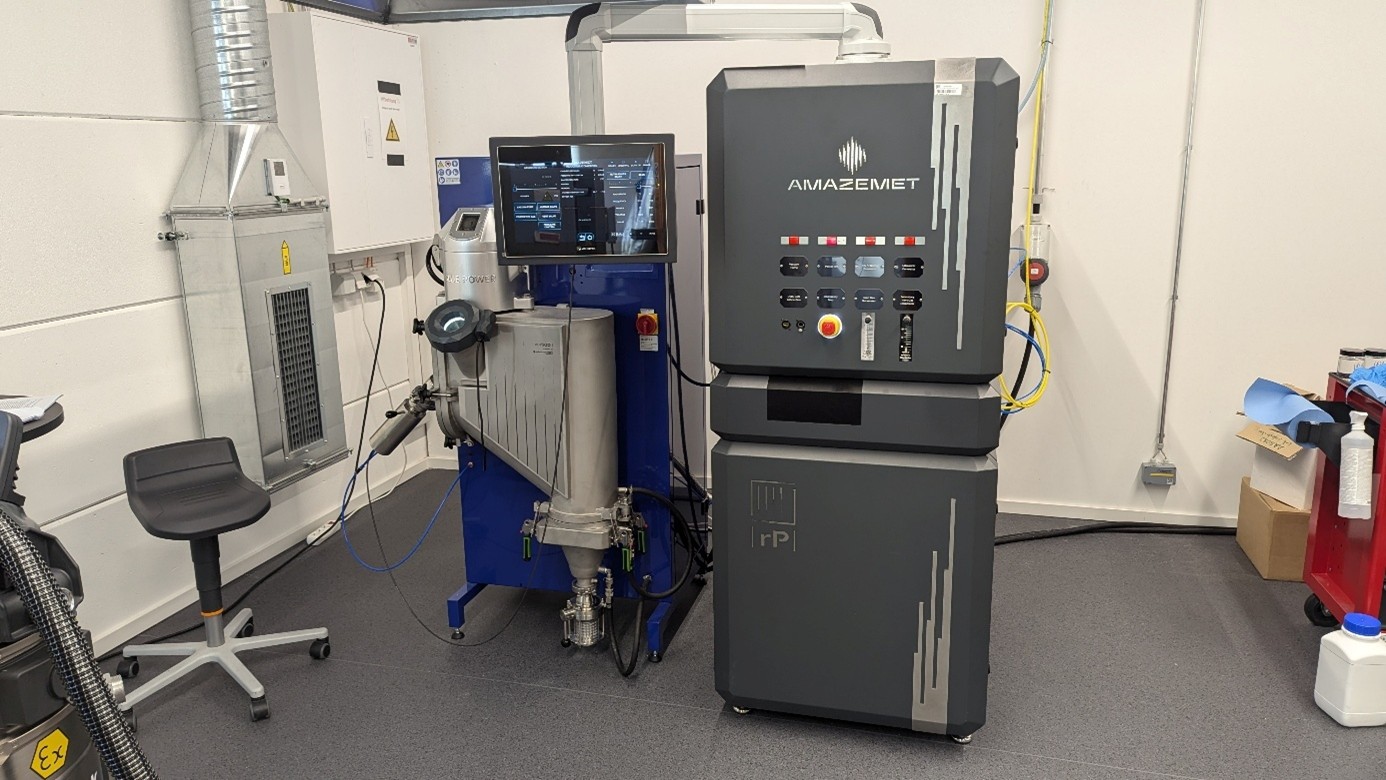

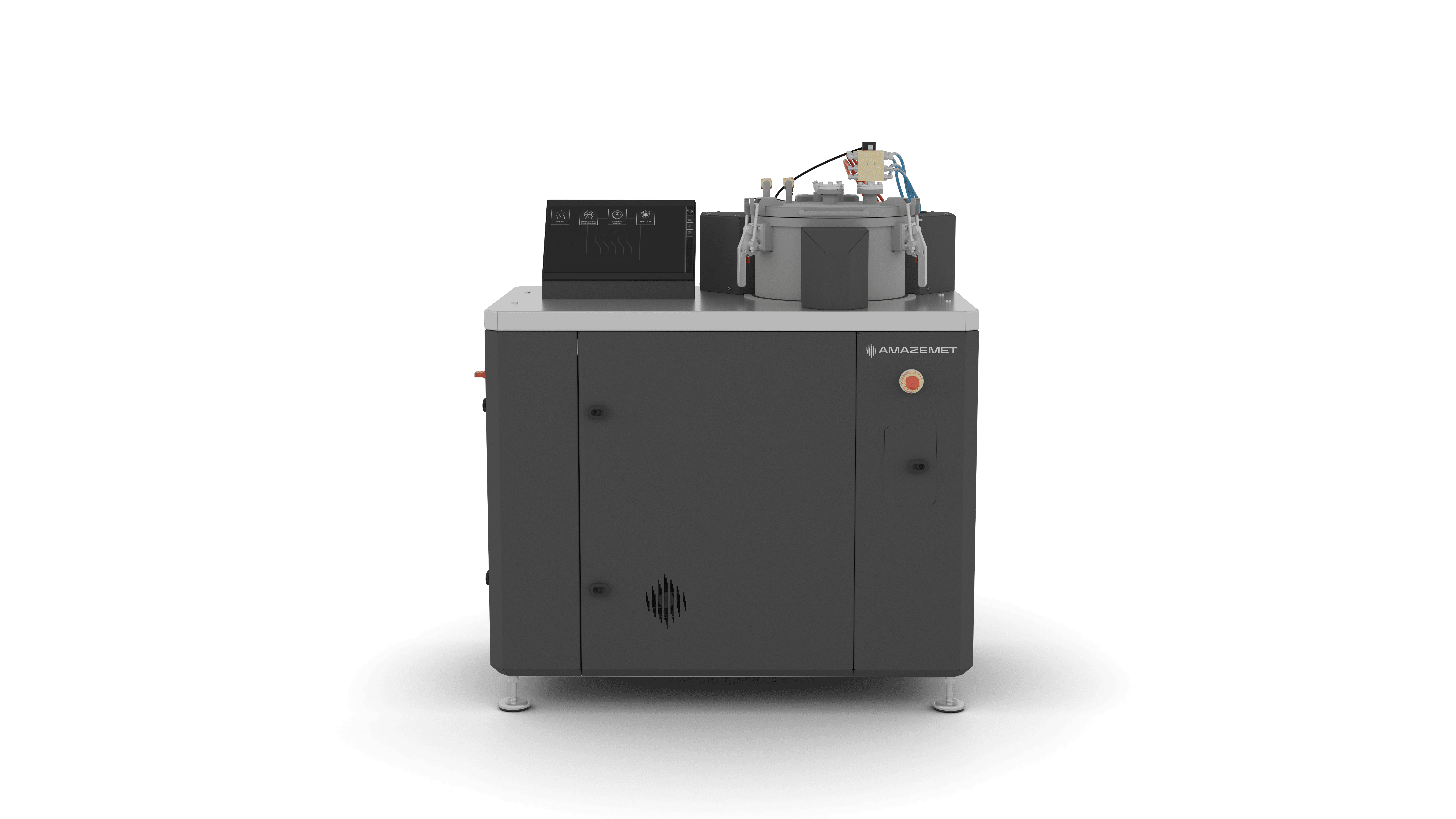

rePOWDER

A cutting-edge ultrasonic atomization system that allows the direct production of high-purity metal powders from raw materials, enabling customized compositions for luxury jewelry applications.

inFURNER

inFURNER – A high-vacuum furnace designed for refining and heat-treating precious metal alloys, improving their purity and mechanical properties while eliminating oxidation risks.

FREEDOM IN METAL AM

DEVELOPMENT & PRODUCTION

RESEARCH PARTNERSHIP

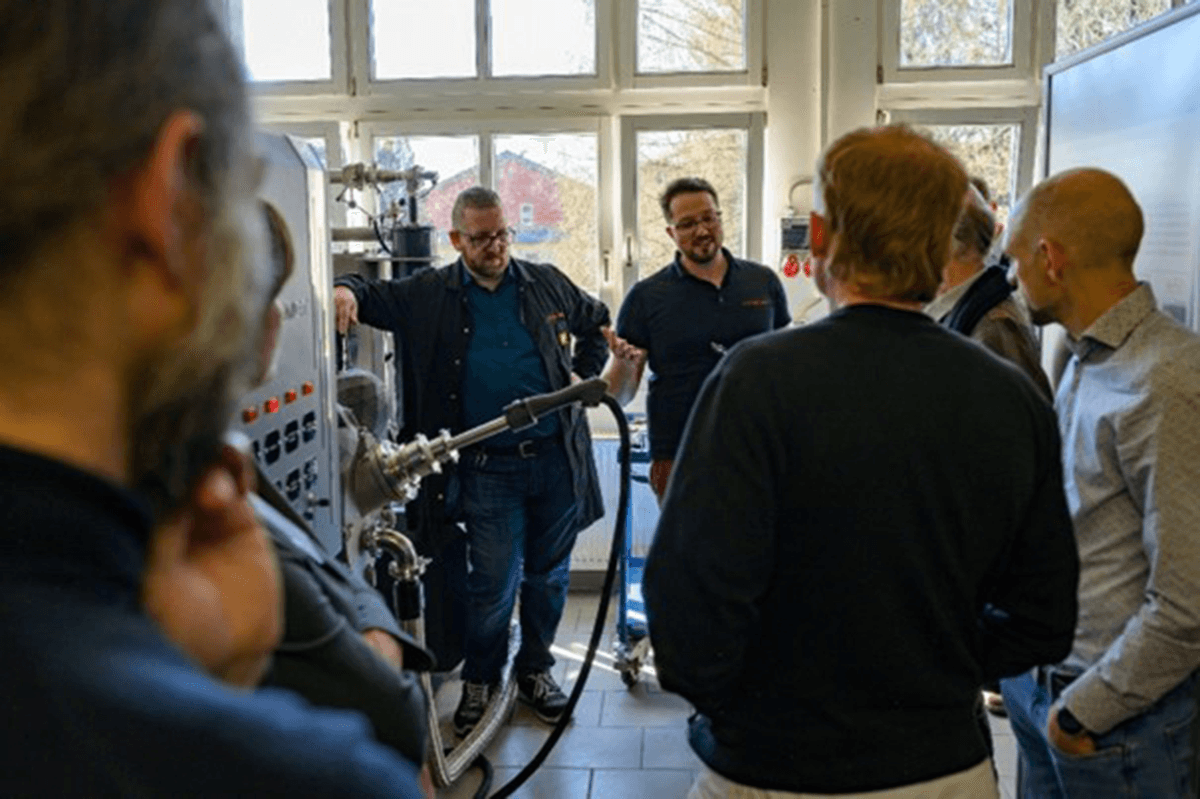

Research Partnership Opportunities in the Jewelry Industry with AMAZEMET

Unlock the full potential of innovative materials and advanced manufacturing techniques with AMAZEMET. As a leader in material science and ultrasonic atomization, we offer unparalleled solutions for developing high-performance alloys and optimizing precious metal production. Our research-driven approach, combined with state-of-the-art technologies, can help jewelry manufacturers overcome traditional processing challenges while enabling the creation of exquisite, durable, and sustainable jewelry.

Explore collaboration opportunities with AMAZEMET for cutting-edge jewelry material innovations. Whether you aim to enhance gold alloys, recycle precious metal waste, or develop new metal compositions for unique designs, our advanced technologies can provide the solutions you need. We actively engage in scientific research and are always open to forging strong partnerships that push the boundaries of what’s possible in the jewelry industry.

ENABLING MATERIALS FOR CUTTING-EDGE APPLICATIONS

Explore Our Work in Action

Discover how AMAZEMET supports research and innovation through real-world collaborations and deep technical insights

Case Studies

Our case studies showcase how we’ve supported partners across industries with tailored solutions—from alloy development to process optimization. They focus on real challenges and how our technology helped turn ideas into results.

Application Notes

Application notes provide a deeper look into the technical aspects of our systems, methods, and materials. They’re ideal for researchers and engineers seeking detailed knowledge and insights to guide their own experiments and development work.

LET’S TALK

Redefine Jewelry Manufacturing with AMAZEMET

Discover how ultrasonic atomization and advanced heat treatment can transform your jewelry production.

Contact us today to get a quote for your customized rePOWDER setup.