Freedom in Metal AM Develompent & Production

Aluminum Alloys: Lightweight Materials for Modern Engineering

Aluminum Alloys: Lightweight Materials for Modern Engineering

Combining low density, excellent corrosion resistance, and good mechanical strength, aluminum alloys are among the most versatile materials in aerospace, automotive, and additive manufacturing.

ALUMINUM ALLOYS

Aluminum Alloys: Balancing Light Weight, Corrosion Resistance, and Printability

Introduction

Aluminum (Al) has long been valued as a lightweight, corrosion-resistant, and affordable structural material. When alloyed with elements such as silicon, magnesium, or scandium, aluminium develops an exceptional balance of properties, making it a foundation of transportation, energy, and consumer applications. Traditional alloys like AlSi10Mg are widely used in additive manufacturing due to their printability and mechanical performance, while Al-Mg-Sc systems enable even higher strength-to-weight ratios.

In powder form, aluminum alloys are essential to 3D printing and advanced manufacturing technologies, enabling the production of lightweight, complex geometries that cannot be achieved by traditional methods. Their role is critical in pushing the boundaries of design freedom in aerospace components, electric vehicles, and energy storage systems.

Aluminum (Al) has long been valued as a lightweight, corrosion-resistant, and affordable structural material. When alloyed with elements such as silicon, magnesium, or scandium, aluminium develops an exceptional balance of properties, making it a foundation of transportation, energy, and consumer applications. Traditional alloys like AlSi10Mg are widely used in additive manufacturing due to their printability and mechanical performance, while Al-Mg-Sc systems enable even higher strength-to-weight ratios.

In powder form, aluminum alloys are essential to 3D printing and advanced manufacturing technologies, enabling the production of lightweight, complex geometries that cannot be achieved by traditional methods. Their role is critical in pushing the boundaries of design freedom in aerospace components, electric vehicles, and energy storage systems.

METAL AM

The Challenge of Accessing Specialized Aluminium Alloy Powders

Standard aluminum powders exist in abundance, but they often fail to meet the specific needs of advanced research and manufacturing.

Most aluminum powders are produced for bulk industries and standardized grades. While this suits large-scale casting and conventional use, it leaves advanced engineering projects with limited options. Common challenges include:

01

Oxidation Sensitivity

Aluminium’s natural oxide layer can affect powder flowability and printability if not carefully controlled.

02

Limited Alloy Options

Catalogs typically focus on established alloys such as AlSi10Mg, leaving little room for novel compositions like Al-Mg-Sc, Al-Zr, or Al-Li systems.

03

High Minimum Orders

Suppliers often require purchases of tens or hundreds of kilograms, which is impractical for small-scale R&D.

04

Long Lead Times

Special requests for non-standard aluminium alloy powders can take months, delaying prototype development.

These barriers slow down innovation in lightweight design, additive manufacturing, and energy applications, where rapid iteration and alloy flexibility are essential.

These barriers slow down innovation in lightweight design, additive manufacturing, and energy applications, where rapid iteration and alloy flexibility are essential.

AMAZEMET

Pathways to Tailored Aluminum Alloy Powders

Researchers and manufacturers can move beyond standardized aluminum powders by leveraging specialty suppliers or in-house atomization systems.

Two strategies enable access to customized aluminium alloy powders:

- Specialty Powder Providers: Advanced materials suppliers can produce small-batch aluminum alloy powders, fine-tuned in terms of chemistry, purity, and particle size distribution. This ensures compatibility with cutting-edge additive manufacturing and specialized coating techniques.

- In-House Atomization: With systems such as rePOWDER, engineers can produce aluminum alloy powders directly on-site, adjusting compositions, adding alloying elements, or refining particle morphology to match specific project requirements.

Both solutions allow researchers to bypass the rigidity of standard alloys and unlock new possibilities in lightweight structures, high-strength Al-Mg-Sc alloys, and novel AM-compatible materials.

METAL POWDERS PRODUCTION

AMAZEMET: Enabling Advanced Aluminium Powder Development

AMAZEMET bridges the gap between commodity aluminum powders and advanced R&D needs by providing small-batch, customized solutions.

At AMAZEMET, we understand that next-generation aerospace, mobility, and energy projects often demand aluminum alloys that go far beyond standard catalog options. We focus on:

Custom powder formulations

including modifications of AlSi10Mg, Al-Mg-Sc, and experimental Al-based alloys.

Flexible order volumes

from grams for research validation to several kilograms for pilot manufacturing.

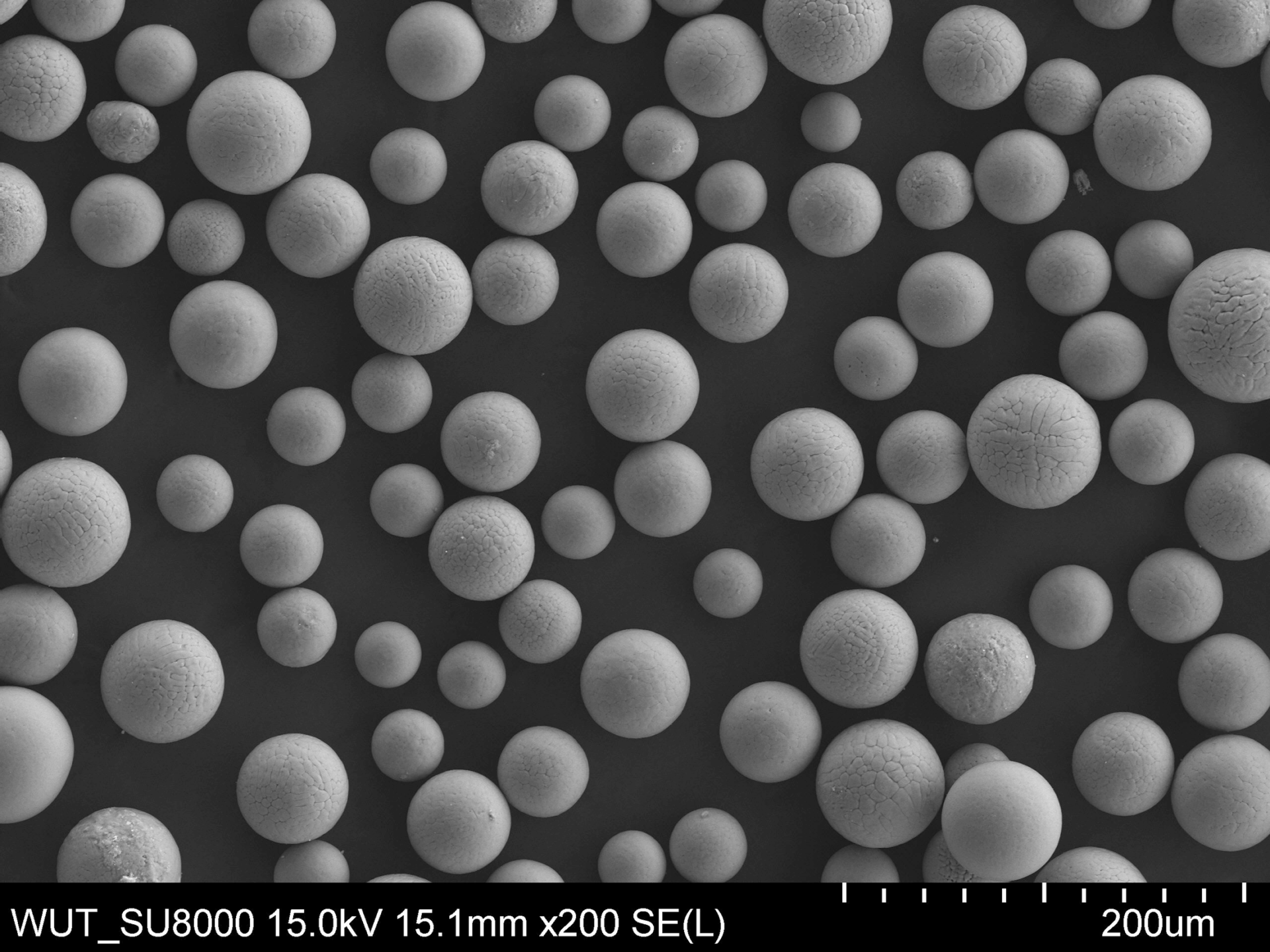

Consistent powder quality

ensuring spherical morphology, high flowability, and minimized oxidation.

AMAZEMET SERVICES & REPOWDER

AMAZEMET Services & rePOWDER: Aluminum Alloy Solutions

From tailored powders to in-house powder production, AMAZEMET supports the entire aluminum alloys development process.

1. Custom Powder Production Services (Small Batches):

- Specialized compositions optimized for AM and coating technologies.

- Scalable volumes suited to research and prototype production.

- Fast turnaround, enabling rapid design iteration.

2. rePOWDER Atomizer for In-House Production:

- Adapted for aluminum and its alloys, ensuring controlled processing despite oxidation sensitivity.

- Flexible alloy design, allowing researchers to test new Al systems beyond standard grades.

- Secure in-house operation, protecting proprietary formulations and accelerating development cycles.

BOOST YOUR PROJECT WITH AMAZEMET

Whether you need small-batch aluminium alloy powders or in-house production capabilities, AMAZEMET provides the tools to explore lightweight materials at the highest level.