Freedom in Metal AM Develompent & Production

Nuclear Industry: Advancing Materials for Nuclear Applications

The advancement of nuclear energy and research to the related topic depends on cutting-edge materials that can withstand extreme radiation, high temperatures, and corrosive environments. From fuel cladding in reactors to the precise fabrication of isotope targets, material science plays a vital role in ensuring safety, efficiency, and sustainability in the nuclear sector. The application of ultrasonic atomization and high-vacuum heat treatment allows for the development of high-purity, radiation-resistant materials that improve performance and reliability in nuclear applications.

INTRODUCTION

Enhancing Nuclear Technologies with Advanced Materials

The nuclear industry demands high-performance materials capable of withstanding extreme environments, including radiation exposure, high temperatures, and corrosion. From structural components in reactors to isotope production for medical and research applications, material innovations play a critical role in nuclear science. Ultrasonic atomization and high-vacuum heat treatment enable the development of specialized powders and alloys for safer and more efficient nuclear technologies.

NUCLEAR INDUSTRY

Key Challenges in Nuclear Materials

Key Challenges in Nuclear Materials

The nuclear industry faces significant challenges in developing materials that can withstand extreme conditions while maintaining performance and safety. Key issues include achieving high-temperature and corrosion resistance in reactor components and ensuring precision in the production of enriched stable isotopes with optimal powder characteristics.

The nuclear industry faces significant challenges in developing materials that can withstand extreme conditions while maintaining performance and safety. Key issues include achieving high-temperature and corrosion resistance in reactor components and ensuring precision in the production of enriched stable isotopes with optimal powder characteristics.

High-Temperature and Corrosion Resistance

The nuclear industry faces significant challenges in developing materials that can withstand extreme conditions while maintaining performance and safety. Key issues include achieving high-temperature and corrosion resistance in reactor components and ensuring precision in the production of enriched stable isotopes with optimal powder characteristics.

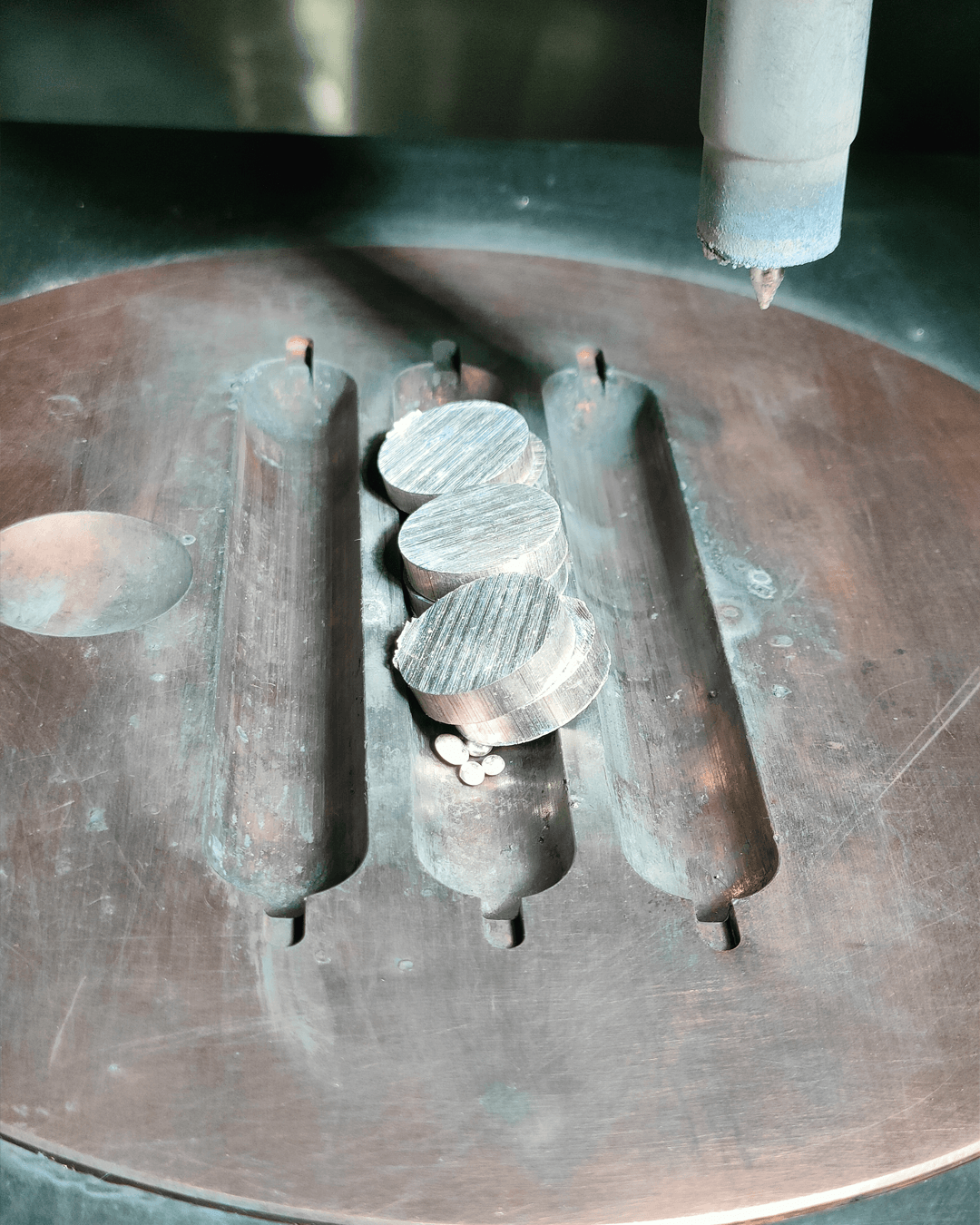

Precision in Isotope Production:

The fabrication of enriched stable isotope targets requires high-purity powders with well-defined morphology and particle size distribution.

CHOOSE YOUR COMPOSITION

Advanced Material Solutions for Nuclear Applications

AMAZEMET offers advanced material solutions that address the unique challenges of the nuclear industry, from enhancing fuel cladding materials to developing high-performance alloys and coatings for extreme reactor conditions. Our ultrasonic atomization technology enables the precise production of zirconium alloys, stable isotope targets, and refractory materials, pushing the boundaries of nuclear materials science.

01

Ultrasonic Atomization of Zirconium Alloys (Zircaloy-4):

The jewelry industry generates significant metal waste during casting, machining, and polishing. Implementing advanced recycling techniques allows for the recovery and reuse of these materials without compromising their purity or mechanical properties. Innovative processes such as ultrasonic reatomization enable the transformation of out-of-spec or excess material back into usable powder, reducing material losses and improving cost efficiency.

02

Stable Isotope Targets for Research and Medicine

Traditional gold jewelry is prone to wear and deformation over time. By carefully alloying gold with elements such as titanium, palladium, or platinum, manufacturers can significantly improve its hardness, scratch resistance, and overall longevity. Controlled alloy development allows for the retention of gold’s aesthetic appeal while enhancing its mechanical properties, making it more suitable for everyday wear.

03

Refractory and Radiation-Resistant Materials

Niobium and tantalum offer an exceptional ability to form stable, colored oxide layers through anodization. This process allows jewelers to create vibrant, corrosion-resistant surfaces without the need for dyes or coatings. By applying precise voltage control during anodization, a wide range of colors can be achieved, expanding creative possibilities in modern jewelry design.

04

Advanced Coatings for Nuclear Components

Protective coatings like NiCrYAl and nickel-based superalloys improve the longevity and performance of nuclear reactor components by reducing oxidation and corrosion under extreme conditions

AMAZEMET

Collaborate with AMAZEMET to Drive Innovation in Nuclear Materials Science

AMAZEMET is at the forefront of developing advanced material solutions for the nuclear industry, focusing on high-performance materials for fuel cladding, isotope production, and radiation-resistant applications. By leveraging cutting-edge technologies such as ultrasonic atomization and high-vacuum heat treatment, we enable precise material customization that meets the stringent demands of nuclear science. Through strategic research partnerships, we aim to accelerate breakthroughs in nuclear materials, providing sustainable solutions that enhance efficiency, safety, and performance. Join us in pushing the boundaries of nuclear technology and contribute to the evolution of safer, more efficient nuclear energy and applications.

Explore our R&D opportunities and collaborate with us to advance the future of nuclear materials.

WHY AMAZEMET

Power the Future of Nuclear Science with Advanced Materials by AMAZEMET

Discover how our innovative material solutions can support nuclear research, reactor technology, and isotope production.

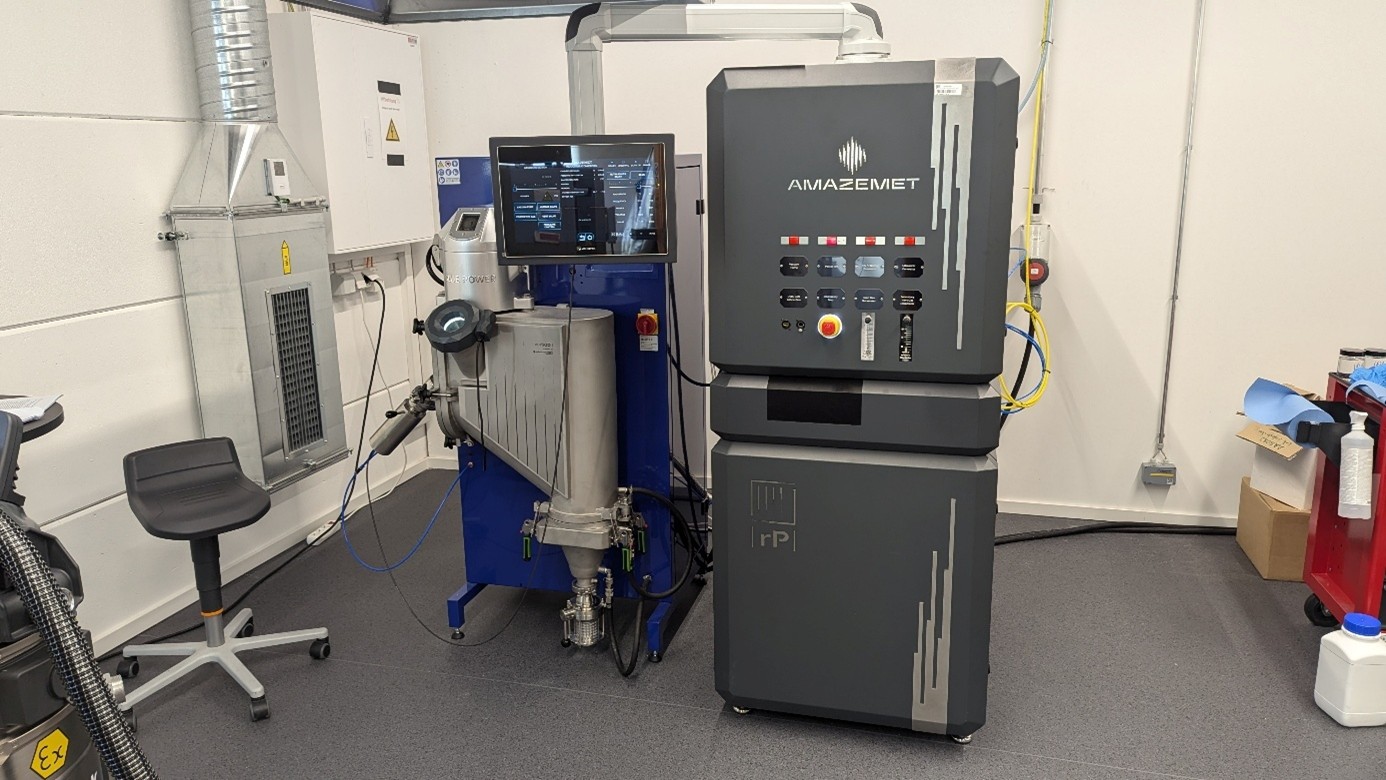

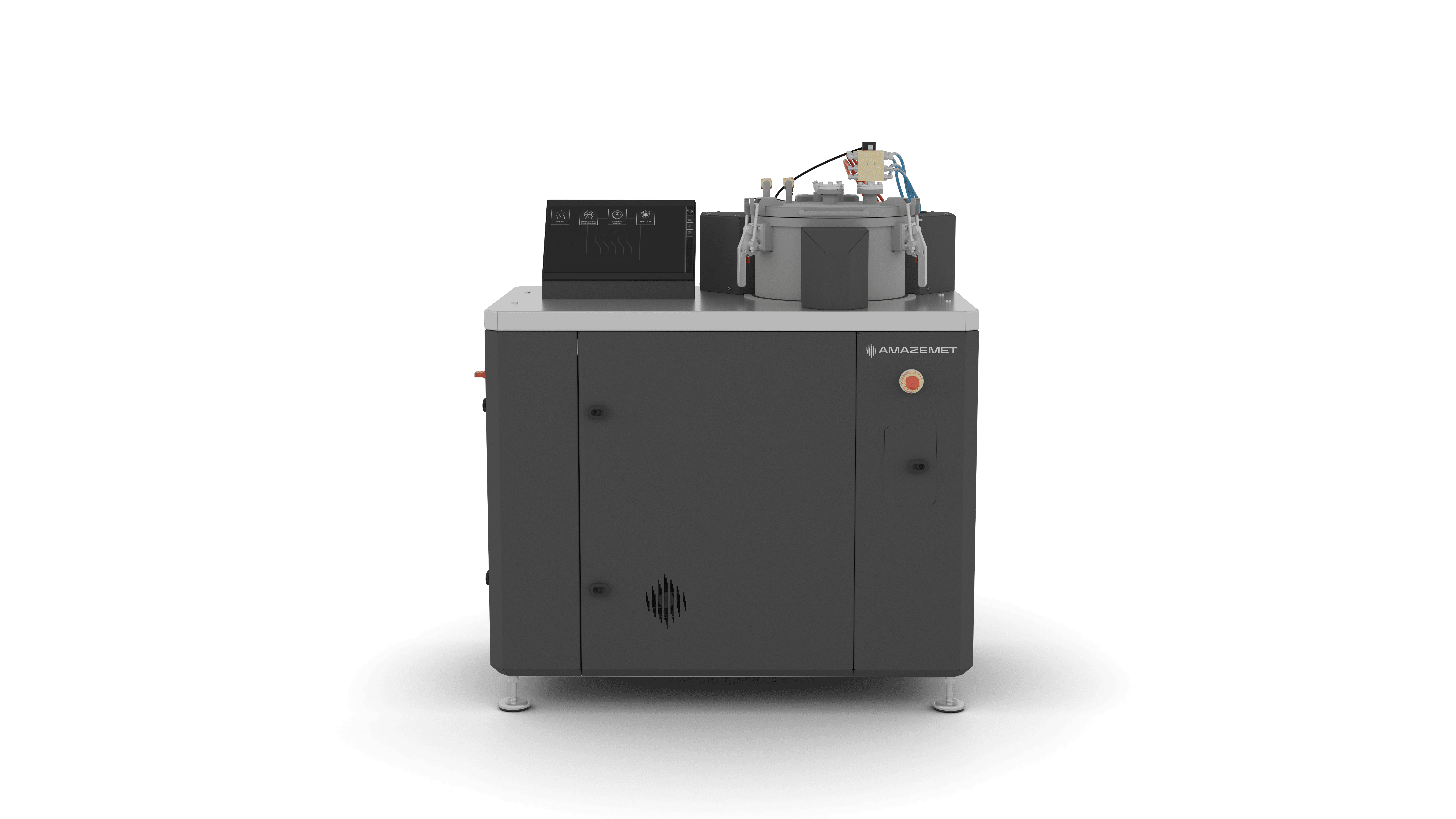

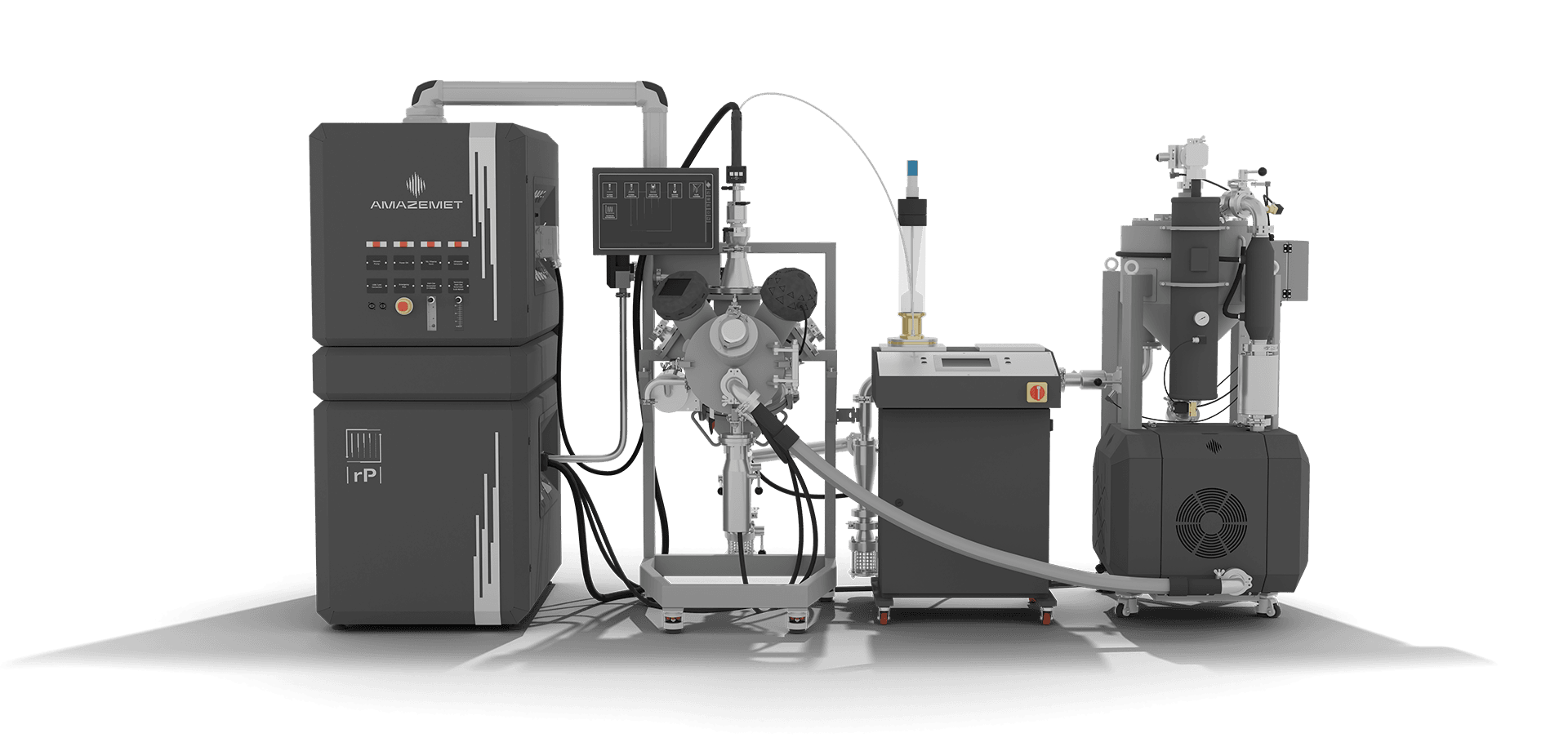

rePOWDER

An ultrasonic atomization system for producing high-purity zirconium, molybdenum as well as low temperature alloys (antimony, bismuth) powders tailored for nuclear applications.

Powder2Powder

A sustainable re-atomization technology that enables the recycling, minimizing waste and enhancing efficiency in nuclear research and manufacturing.

inFURNER

inFURNER – A high-vacuum furnace designed for heat treatment of radiation-resistant materials, optimizing mechanical and thermal properties.

FREEDOM IN METAL AM

DEVELOPMENT & PRODUCTION

ENABLING MATERIALS FOR CUTTING-EDGE APPLICATIONS

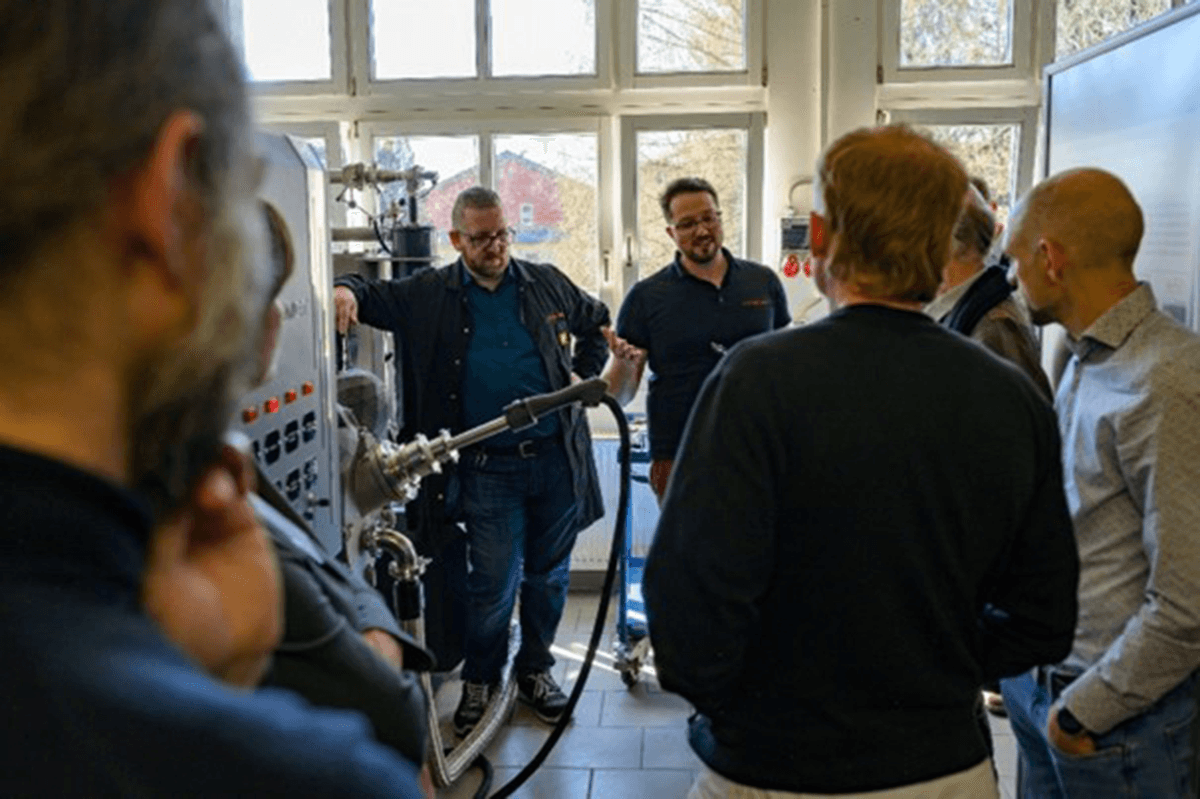

Explore Our Work in Action

AMAZEMET actively contributes to nuclear materials research, supporting innovations in fuel cladding, isotope production, and radiation-resistant materials. Explore our recent scientific publications:

Case Studies

Our case studies showcase how we’ve supported partners across industries with tailored solutions—from alloy development to process optimization. They focus on real challenges and how our technology helped turn ideas into results.

Application Notes

Application notes provide a deeper look into the technical aspects of our systems, methods, and materials. They’re ideal for researchers and engineers seeking detailed knowledge and insights to guide their own experiments and development work.

LET’S TALK

Power the Future of Nuclear Science with Advanced Materials by AMAZEMET

Discover how our innovative material solutions can support nuclear research, reactor technology, and isotope production.

Contact us today to get a quote for your customized rePOWDER setup.