INTRODUCTION

Thermal Spray

Thermal Spray

Thermal spray technologies enable the application of high-performance coatings to enhance wear resistance, corrosion protection, and thermal insulation. These techniques rely on the accelerated deposition of metal and ceramic powders onto surfaces, making them critical for aerospace, energy, biomedical, and manufacturing industries. Among the various methods, Cold Spray, Plasma Spray, and HVOF/HVAF stand out for their ability to produce dense, high-quality coatings for the most demanding applications.

How Thermal Spray Technologies Work

Thermal spray technologies encompass a range of methods that enhance the surface properties of critical components across industries. Whether it’s Cold Spray for temperature-sensitive repairs, Plasma Spray for high-performance coatings, or HVOF/HVAF for dense and wear-resistant layers, each technology offers unique benefits tailored to specific operational demands.

COLD SPRAY

Cold Spray is a solid-state deposition process where metal powders are accelerated to supersonic speeds using a heated, high-pressure gas, such as helium or nitrogen. There are two main variants of this process: High-Pressure Cold Spray (HPCS) and Low-Pressure Cold Spray (LPCS). HPCS typically utilizes helium as the carrier gas, allowing the deposition of materials with higher yield strength, such as Ti-6Al-4V (Grade 5 titanium alloy). High-pressure systems often require chambers for helium gas recovery, making them more economical for large-scale applications. In contrast, LPCS operates at lower pressures with nitrogen and is well-suited for softer materials like aluminum alloys, copper alloys, and commercially pure titanium (CP-Ti). The high-velocity impact causes the particles to deform and bond upon contact with the substrate, forming dense coatings without melting the material. However, due to the cold nature of the process, the bond strength of Cold Spray coatings is generally inferior to that of HVOF and Plasma Spray, as it relies only on mechanical interlocking and adhesion rather than metallurgical bonding. One of the key advantages of Cold Spray is that it does not significantly affect the substrate material, making it highly compelling for repair applications in aerospace, defense, and industrial sectors where minimal heat input is essential to prevent thermal distortion or degradation of components. However, repairing complex parts can be challenging due to the small stand-off distance required between the spray gun and the substrate, typically around 20 – 100 mm, limiting access to intricate geometries.

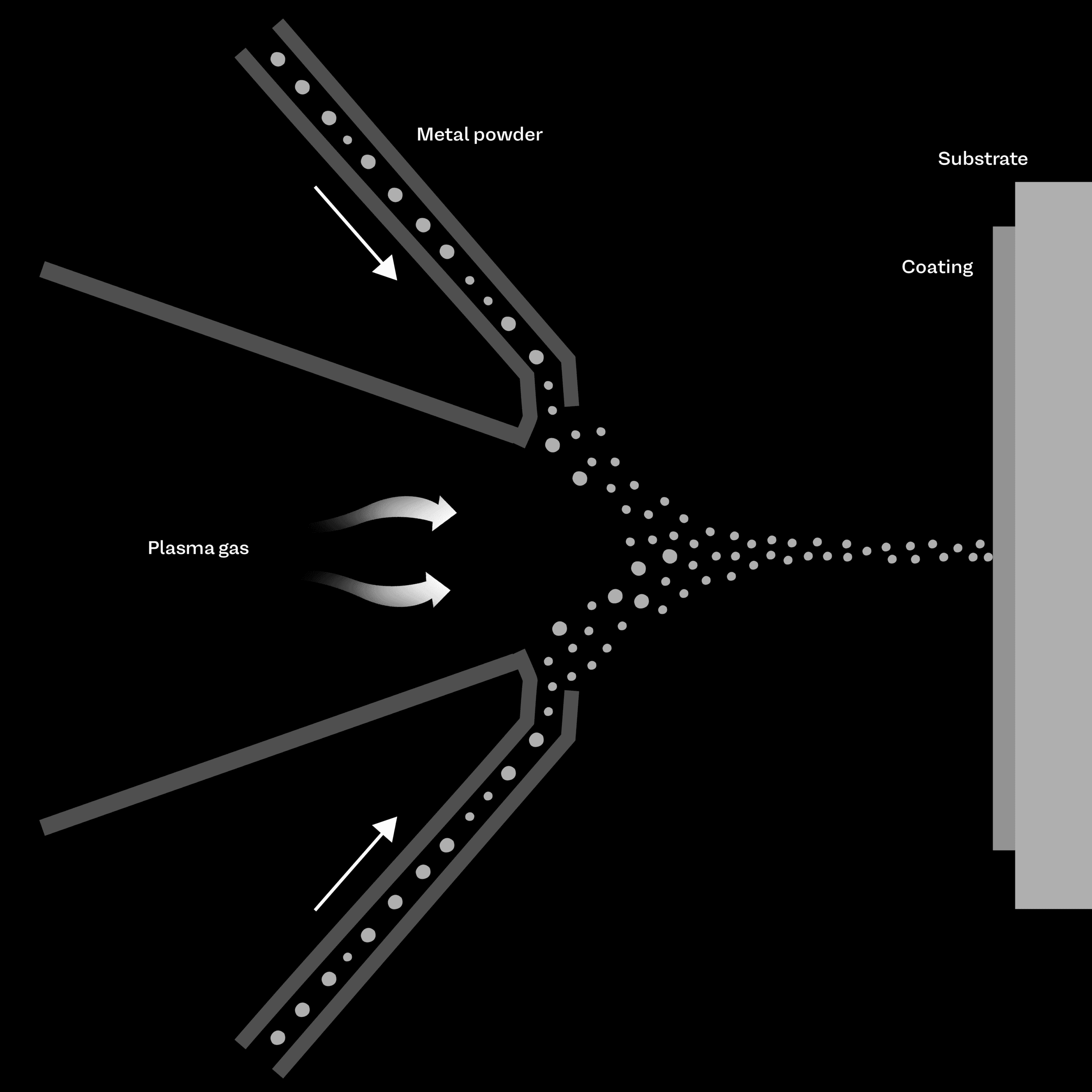

PLASMA SPRAY

Plasma Spray utilizes a high-temperature plasma jet to melt and propel powder particles toward the substrate. The process typically employs argon, nitrogen, or hydrogen gases to generate plasma temperatures exceeding 10,000°C, ensuring full melting of the powder before impact. Upon contact with the surface, the molten particles rapidly solidify, forming a uniform coating. The most common type of Plasma Spray is Atmospheric Plasma Spray (APS), which operates in an open atmosphere and is limited to materials that are not sensitive to oxidation. An intermediate option is Low Pressure Plasma Spray (LPPS), which operates at reduced pressure levels compared to APS, lowering oxidation risks while maintaining lower costs than VPS. Vacuum Plasma Spray (VPS) is used for applications requiring the deposition of metallic alloys or oxidation-sensitive materials. VPS involves placing the entire system in a vacuum chamber, significantly increasing costs but allowing for a controlled environment that prevents oxidation and enables the deposition of highly reactive metals such as titanium, nickel-based superalloys, and refractory metals like tungsten. Plasma spray is widely used for thermal barrier coatings, corrosion-resistant layers, and biomedical implants due to its ability to process a broad range of materials, including ceramics and refractory metals.

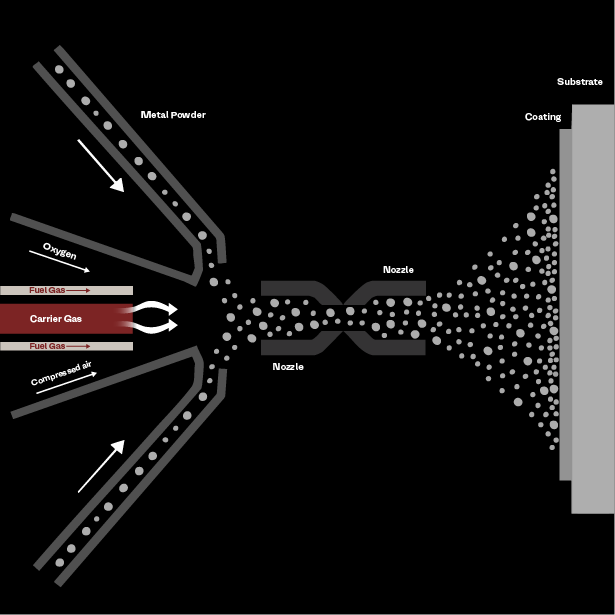

HVOF/HVAF (High-Velocity Oxygen-Fuel / Air-Fuel Spray)

HVOF and HVAF are combustion-based spray processes that propel powder particles at supersonic velocities using a mixture of fuel (such as propane, kerosene, or natural gas) and oxygen or air. The controlled combustion process heats the powder to a semi-molten state while maintaining high kinetic energy. Upon impact with the substrate, the particles create a dense and well-bonded coating with minimal porosity.

Differences Between HVOF and HVAF

- HVOF (High-Velocity Oxy-Fuel ): Utilizes oxygen as the oxidizer, resulting in higher flame temperatures (around 2,800–3,000°C). This allows for efficient melting of harder materials but can introduce some oxidation.

- HVAF (High-Velocity Air-Fuel Spray): Uses compressed air as the oxidizer, reducing the flame temperature (around 1,800–2,000°C). This minimizes oxidation and allows for superior coatings of oxygen-sensitive materials, such as WC-Co and stainless steels.

Economic Aspects

HVAF tends to be more cost-effective due to the use of air instead of pure oxygen, reducing operational costs. Additionally, HVAF coatings typically have lower oxide content and higher density, leading to extended component lifespan and reduced rework or recoating needs.

Applications and Commonly Deposited Alloys

- HVOF: Preferred for wear-resistant coatings in aerospace and energy industries, commonly depositing WC-Co, Inconel alloys, Stellite alloys, and chromium carbide-based coatings.

- HVAF: Ideal for corrosion protection and highly wear-resistant applications, used for depositing stainless steels, nickel-based alloys, titanium alloys, and tungsten carbide-based coatings.

HVOF/HVAF coatings are widely used in aerospace (turbine blades, landing gear), power generation (boiler coatings, turbine components), and industrial machinery (valves, hydraulic cylinders, rollers) due to their ability to provide dense, high-performance protective layers.

THERMAL SPRAY TECHNOLOGY

Key Challenges in Thermal Spray Powders

01

Cold spray

Particles in the process must exceed a critical velocity to activate the adiabatic shear instability phenomenon, which promotes the formation of dense coatings. Additionally, cold spray coatings often suffer from lower bond strength due to the absence of metallurgical bonding, relying purely on mechanical interlocking and adhesion. Another major challenge is the difficulty in depositing brittle or hard materials, as they do not deform well upon impact, leading to poor coating integrity. Residual porosity and lower cohesion can also affect the long-term performance of cold spray coatings. Furthermore, the high gas consumption and the cost of helium in high-pressure systems make economic feasibility a key concern, necessitating gas recovery systems for sustainability.

02

Plasma Spray

Demands controlled particle size and spheroidization for optimal melting and uniform coatings. Process stability and the high temperatures involved require advanced powder feedstock to ensure homogeneity. Oxidation remains a challenge, particularly in APS, requiring the use of vacuum or low-pressure systems to maintain material integrity. Additional challenges include thermal stresses induced during rapid cooling, which can lead to coating delamination or cracking. The inherent porosity of plasma-sprayed coatings can also affect mechanical properties and corrosion resistance, necessitating post-processing treatments such as sealing or heat treatment. Furthermore, complex geometries can be difficult to coat uniformly, as shadowing effects and variations in heat input can result in inconsistent deposition and coating thickness. The high energy consumption and expensive equipment requirements further contribute to the cost challenges of plasma spray processes.

03

HVOF/HVAF

While they benefit from highly spherical powders with minimal porosity to ensure dense, wear-resistant coatings, multiple challenges emerge based on current review articles. The high kinetic energy can lead to substrate damage or excessive residual stress, necessitating careful parameter optimization and fixturing. Additionally, controlling oxidation (particularly in HVOF, due to its reliance on pure oxygen) can be difficult when spraying oxidation-sensitive materials, requiring precise adjustments of fuel-to-oxidizer ratios. Residual stresses can build up due to rapid cooling, leading to potential microcracking or delamination if not managed properly. Complex geometries pose another issue, as ensuring uniform coating thickness around sharp corners or recessed areas requires careful manipulation of spray angles and distances.

Worth mentioning is the nozzle wear when spraying highly abrasive feedstocks (e.g., carbides) at high velocity, which can alter the spray geometry over time and lead to inconsistent coatings unless regularly monitored and replaced. Powder feed rates must also be carefully controlled to ensure adequate melting and minimize overspray or waste. Surface preparation is critical, as contaminants or inadequate roughening can reduce adhesion and compromise coating integrity. Finally, the environmental and safety aspects—such as high noise levels, off-gas handling, and combustion exhaust—necessitate specialized spray booths and air filtration systems, adding to overall operational costs.

In practice, the choice between HVOF and HVAF depends on the oxidation sensitivity of the feedstock and the desired coating properties, requiring a balanced approach to manage thermal input, velocity, and material compatibility. Cost-effectiveness, production throughput, and part geometry all play a role in determining which technology best suits a given application.

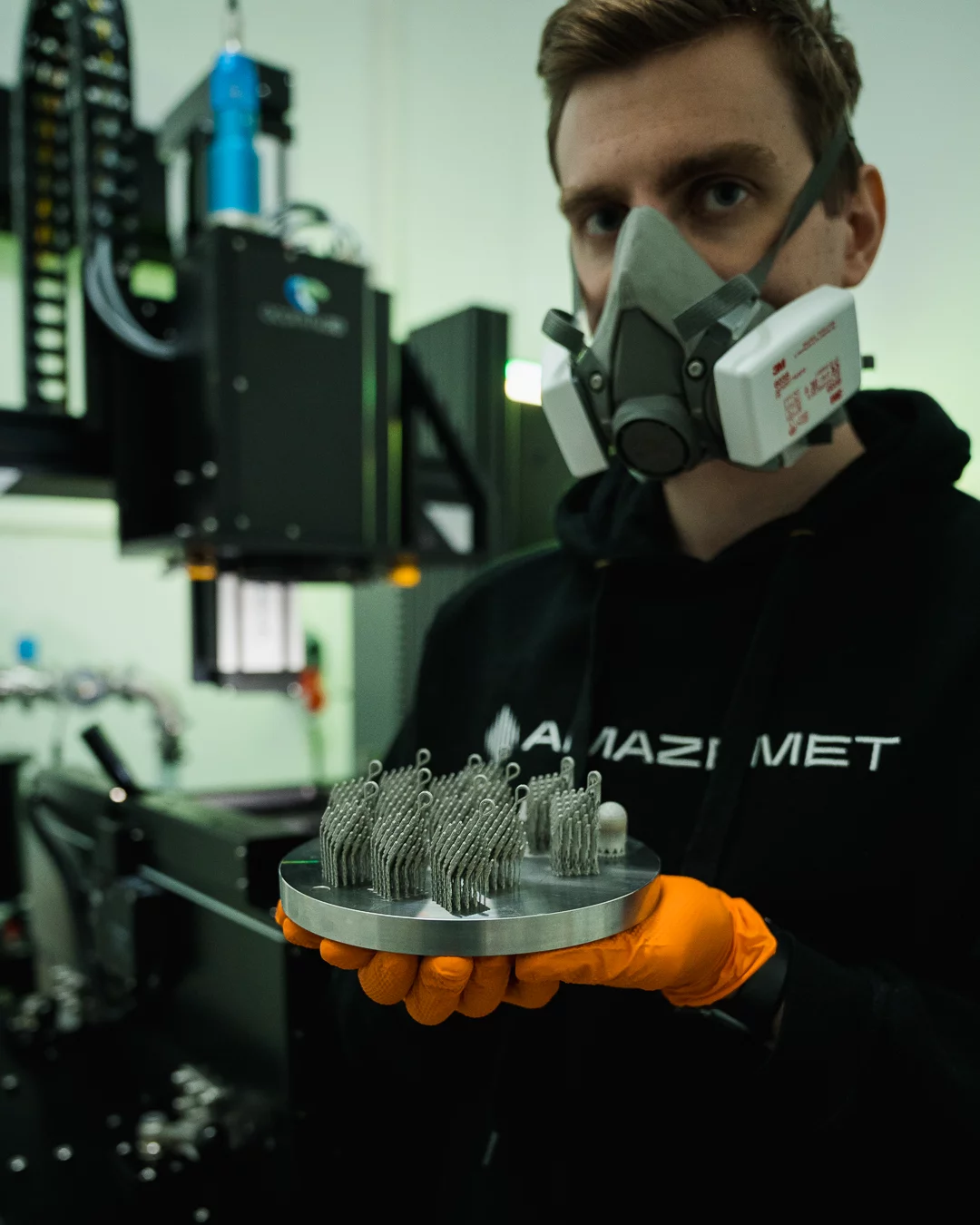

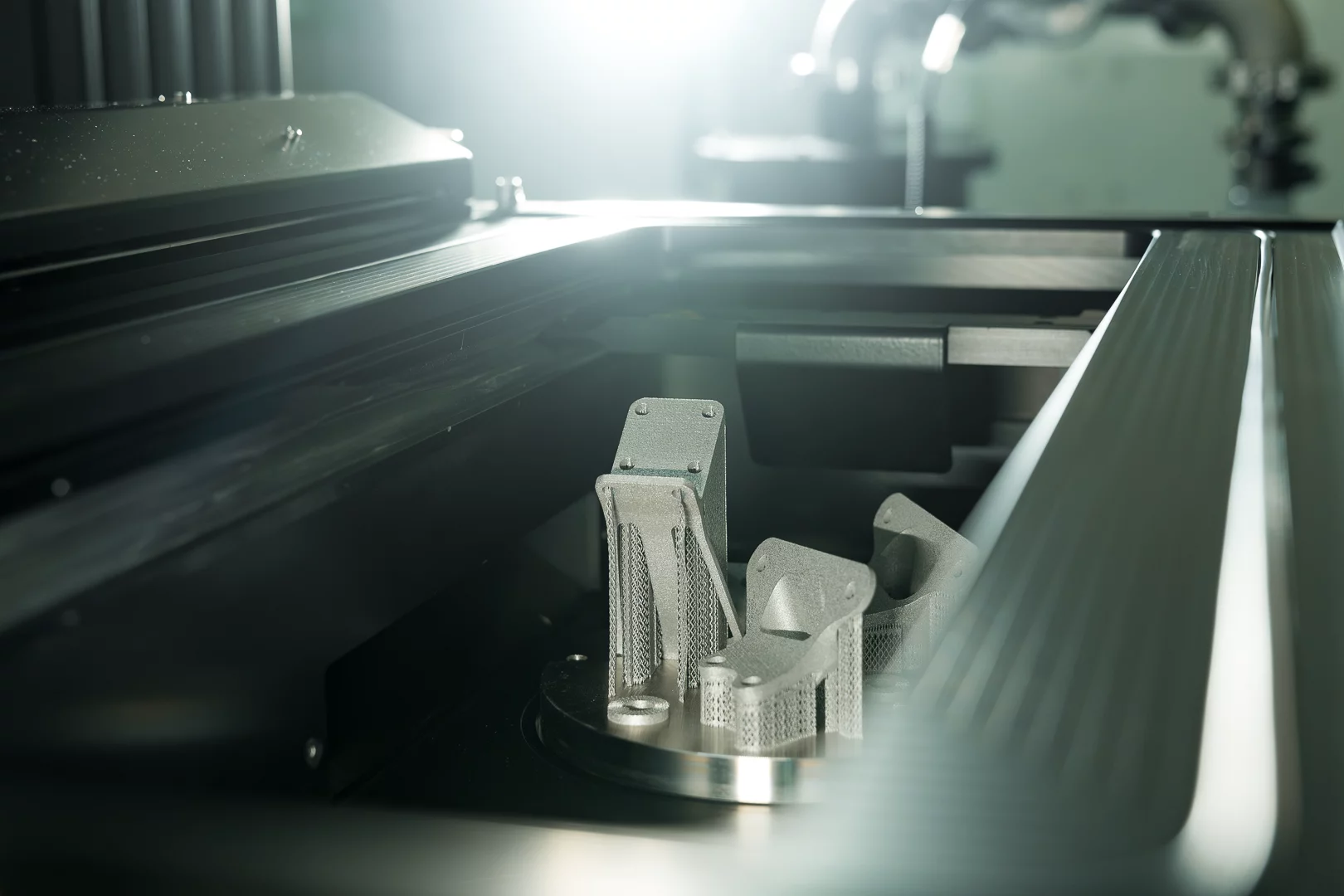

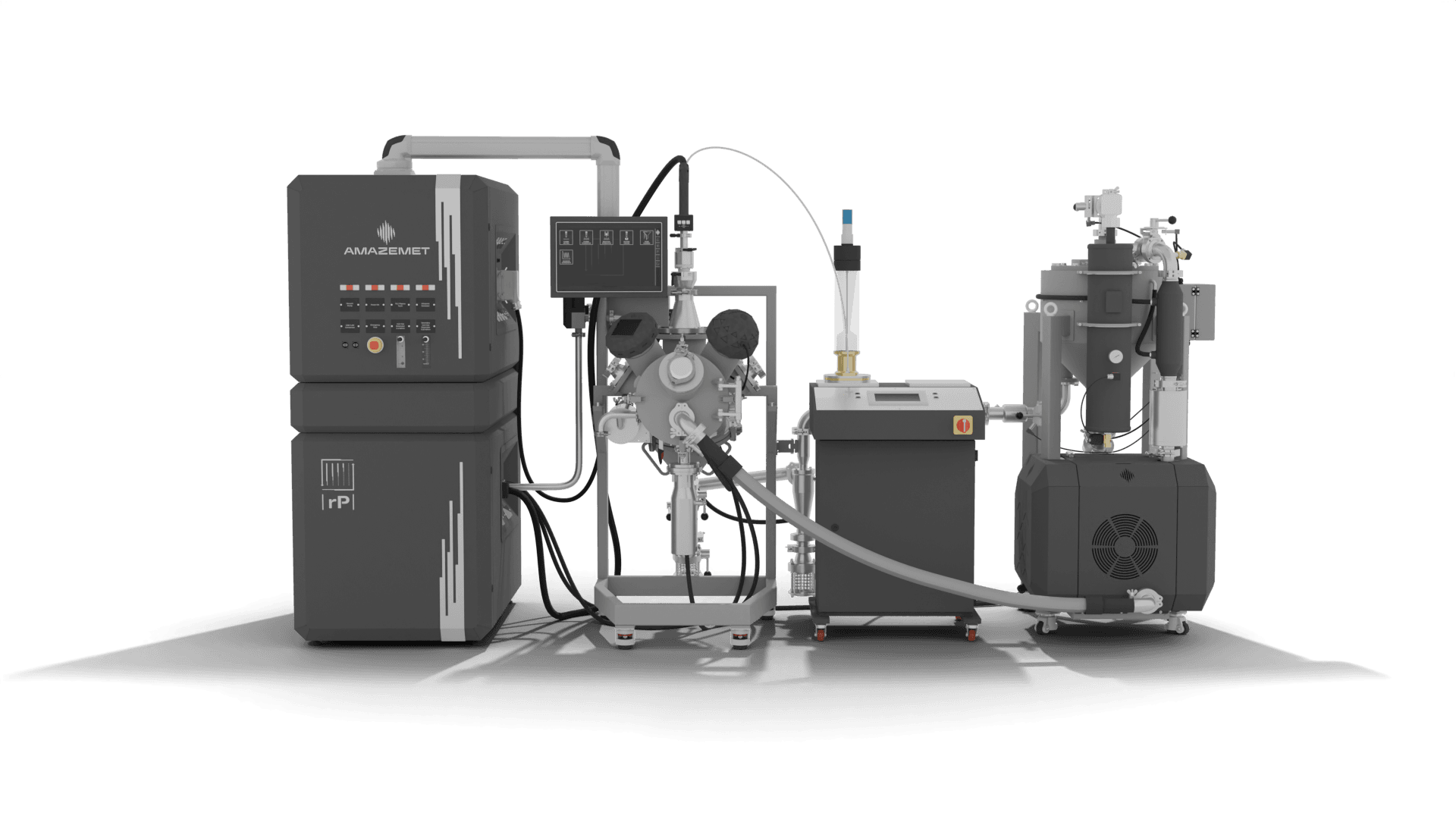

Ultrasonic Atomization for High-Quality Thermal Spray Powders

AMAZEMET's rePOWDER ultrasonic atomization technology offers a breakthrough in producing powders specifically tailored for Cold Spray, Plasma Spray, and HVOF/HVAF applications. rePOWDER leverages high-frequency ultrasonic vibrations to break molten metal into microdroplets. This precise control over droplet formation results in uniform, high-quality feedstock with minimal oxygen pickup—a crucial parameter not only for LPBF but also for thermal spray processes that rely on oxygen-sensitive materials.

By combining the operational simplicity of a small footprint with the advanced control of ultrasonic atomization, rePOWDER significantly reduces oxygen pickup and ensures consistent powder morphology. This translates to dense, high-quality coatings in thermal spray processes—critical for applications in aerospace, biomedical, and energy sectors.

How rePOWDER Works

- Molten Metal Feed: The chosen alloy is melted in a controlled atmosphere, minimizing contamination.

- Ultrasonic Vibration: High-frequency ultrasound disrupts the molten metal stream, creating fine droplets that rapidly solidify into spherical particles.

- Narrow Particle Size Distribution: Over 80% of the atomized powder typically meets size requirements for powder-based manufacturing, reducing material waste.

Key Advantages for Thermal Spray Applications

- Spherical Powder Morphology: Enhances flowability and uniform coating deposition in Cold Spray, Plasma Spray, and HVOF/HVAF processes.

- Low-Oxidation Powders: Ensures superior bonding and high-performance coatings, particularly for oxidation-sensitive materials.

- Custom Alloy Development: Enables researchers and industry professionals to rapidly create specialized compositions.

- Wide Material Spectrum: From commonly used ductile metals (e.g., aluminum, copper, and iron-based powders) to specialized high-performance alloys frequently researched in thermal spray applications—such as NiCr, Co-based superalloys, MCrAlY, tungsten-based materials, and advanced High Entropy Alloys (HEAs) like HfNbTaZr or MoNbTaVW.

- Compact, Lab-Scale Design: Facilitates quick iteration on alloy compositions and parameter optimization, bridging the gap between laboratory experimentation and industrial-scale production.

Why Choose AMAZEMET?

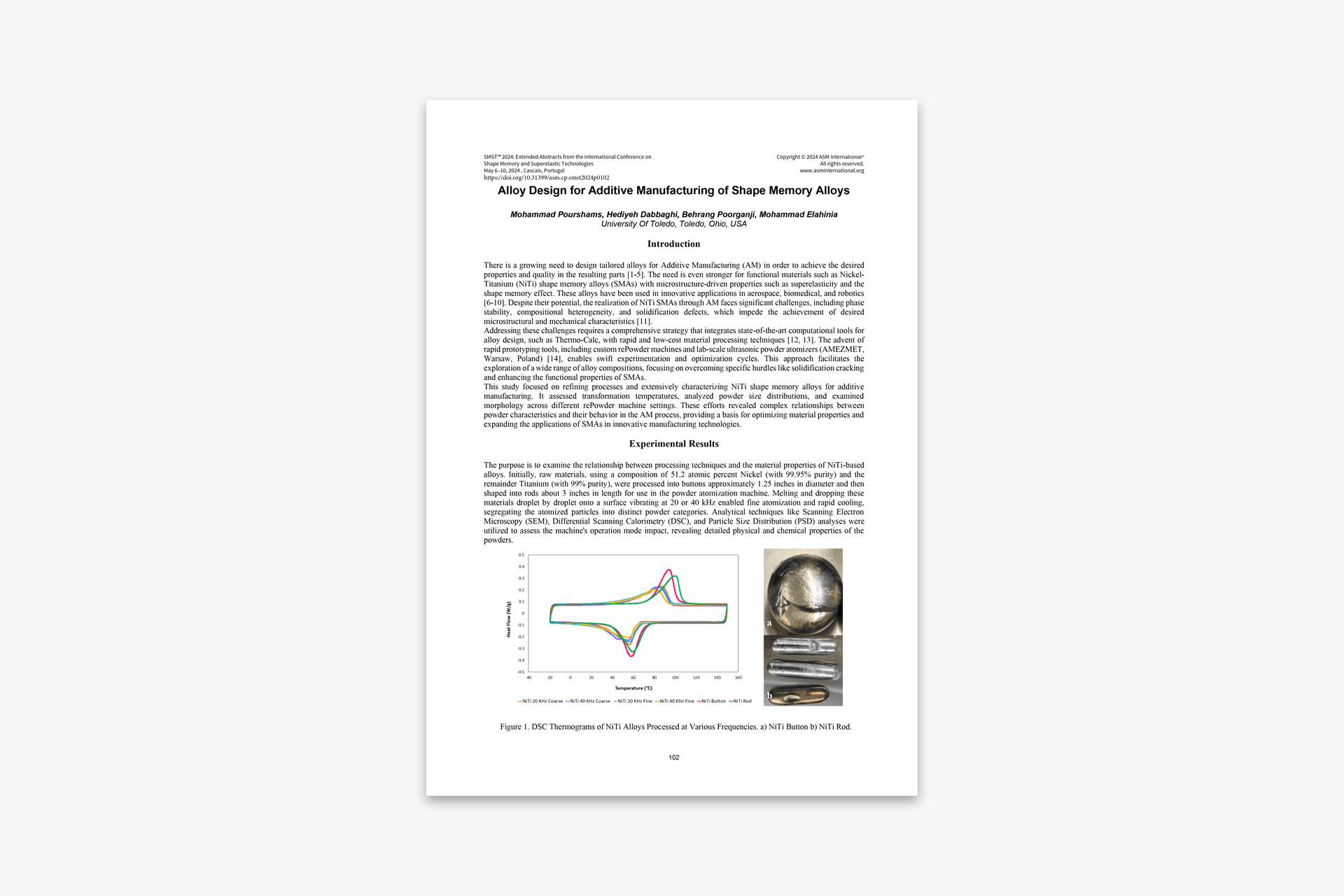

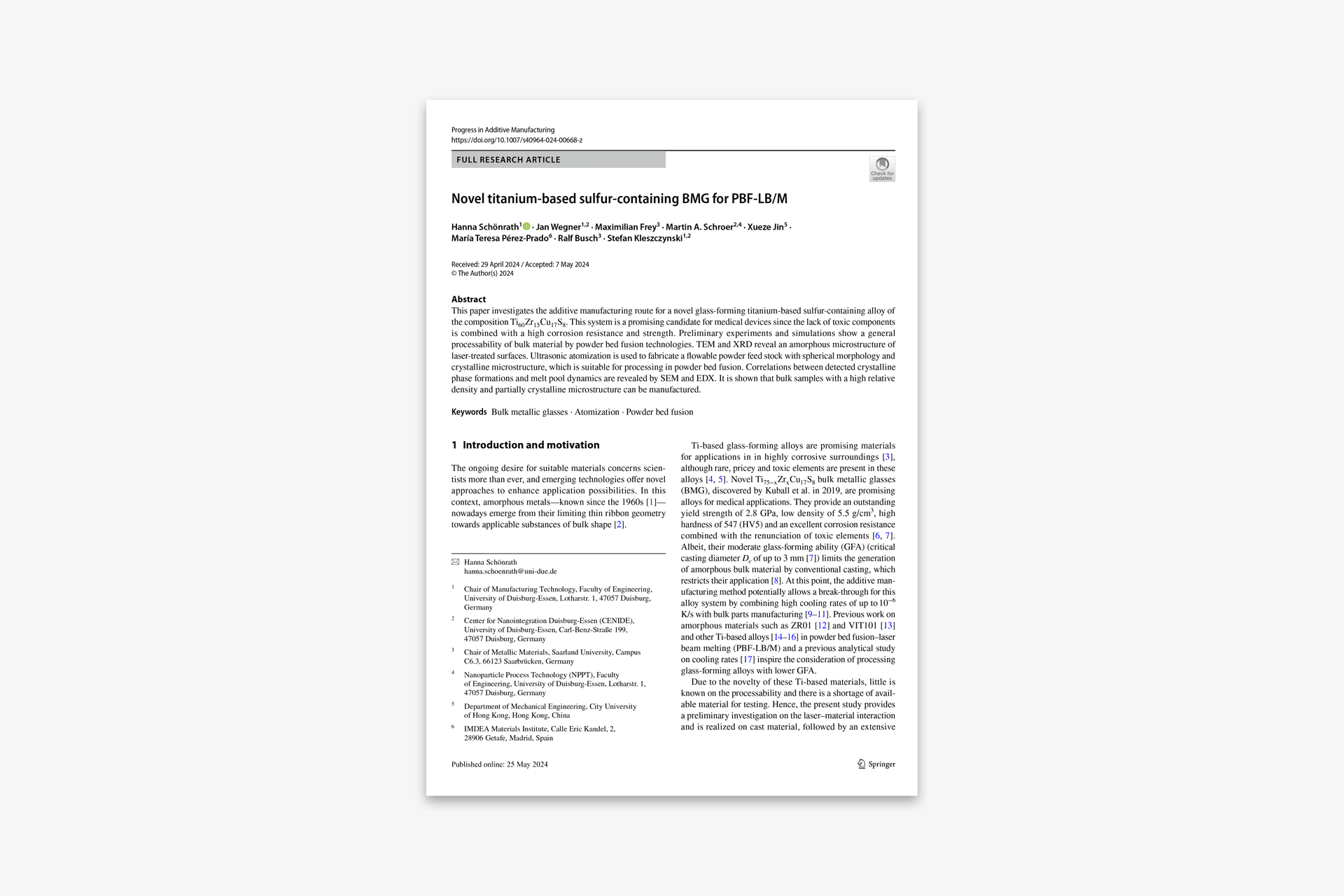

At AMAZEMET, we are materials scientists at heart. Our research and development team is composed of experienced PhD holders, PhD candidates, and engineers who actively publish their work in peer-reviewed journals, advancing the fields of powder metallurgy and additive manufacturing. With a firm grounding in materials science, we are uniquely equipped to tackle the complex challenges of thermal spray processes—from designing novel alloys to optimizing powder characteristics for maximum performance. This expertise drives continuous innovation in our ultrasonic atomization technology, enabling us to develop cost-effective, high-quality feedstock solutions that push the boundaries of what is possible in cold spray, plasma spray, and HVOF/HVAF applications.

Below, we invite you to explore a list of publications made possible by the AMAZEMET team and our ultrasonic atomization technology. These works exemplify our commitment to scientific rigor, real-world applicability, and the ongoing quest to elevate thermal spray research and industrial practice.

OUR CUSTOMERS

Trusted by Innovators Worldwide

AMAZEMET is proud to collaborate with a diverse range of clients who trust our cutting-edge solutions to advance their projects. rePOWDER is currently being used to atomize novel powder compositions in:

ATOMIZATION SERVICES

rePOWDER & Powder2Powder – Your Go-To R&D Powder Atomization Services

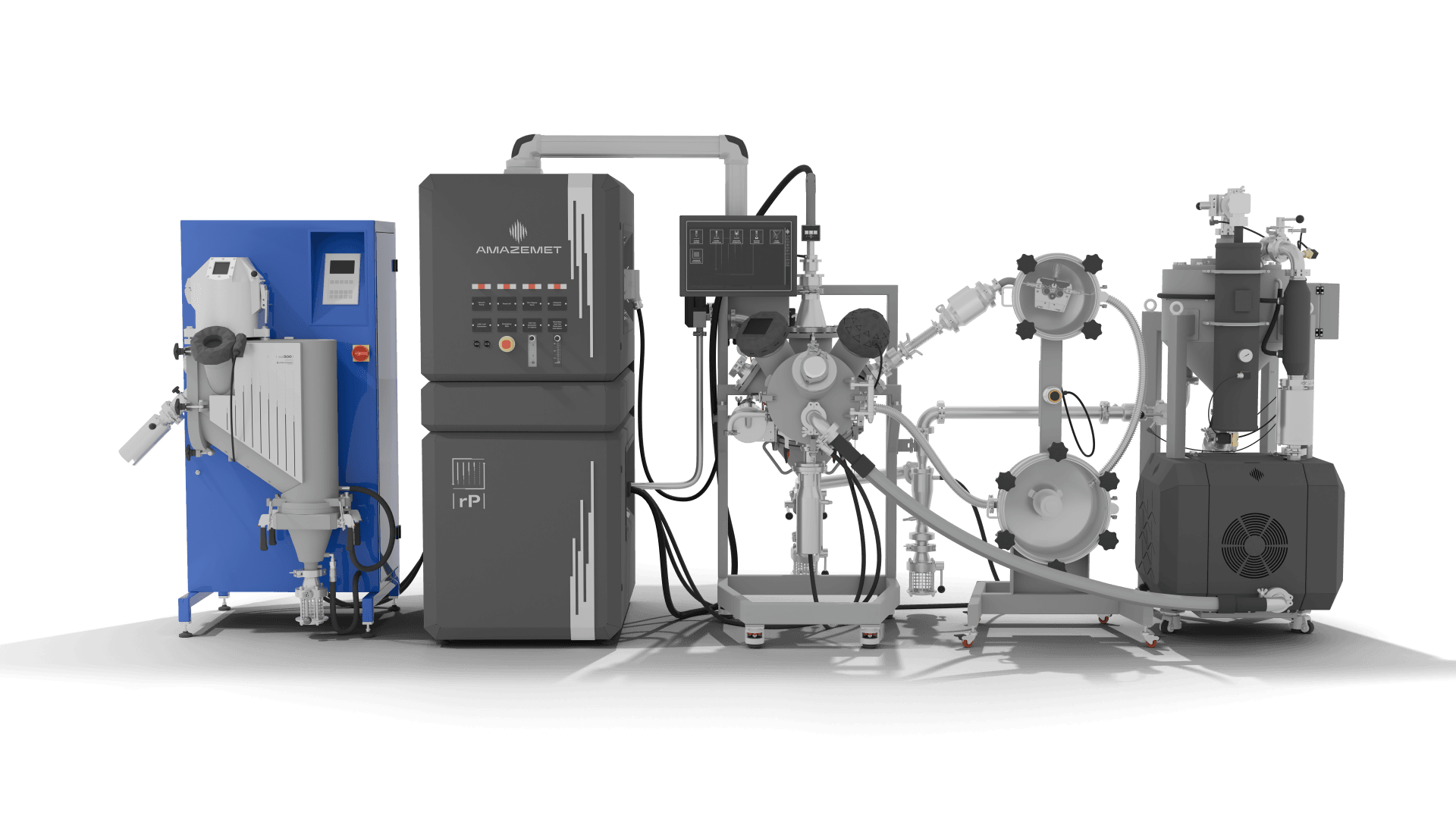

At AMAZEMET, we offer on-demand, high-purity, customizable metal powder solutions using our lab-scale rePOWDER ultrasonic atomization system and our Powder2Powder (P2P) technology for re-atomizing or re-spheroidizing existing feedstock. Both solutions were designed to help R&D teams and industry professionals push the limits of material innovation, all while reducing costs and minimizing waste.

These combined technologies extend beyond the lab to support Cold Spray, Plasma Spray, and HVOF/HVAF processes requiring premium feedstock. Whether you’re developing next-generation materials, refining existing alloys, or scaling up for industrial trials, AMAZEMET’s atomization services help you reach your R&D goals quickly and cost-effectively.

Powder2Powder (P2P): Ultrasonic Re-Atomization & Closed-Loop Recycling

- Transform Irregular or Oversized Particles into highly spherical, satellite-free powders optimized for AM and thermal spray.

- Reuse Existing Feedstock—buy powder once and keep reusing it, minimizing waste and reducing costs.

- Process Blends of Elemental Powders into pre-alloyed materials with precisely tailored chemical compositions.

- Closed-Loop Production that seamlessly integrates with your workflow, reducing disposal and environmental impact.

- Metal Research Multitool capable of handling a broad spectrum of alloys, from everyday metals to high-performance and refractory materials.

rePOWDER: Lab-Scale Atomization for New Alloys

- Small MOQs from just 10 grams, ideal for experimental and iterative research.

- Multiple Materials at No Additional Cost, letting you explore aluminum, magnesium, titanium, nickel superalloys, and more in the same project.

- High Purity & Uniformity thanks to ultrasonic atomization, leading to minimal oxygen pickup.

- Up to 80% of Output meets critical size requirements, reducing waste.

Looking for high-quality thermal spray powders?

Reach out to our AMAZEMET application engineers by using the contact form or our powder order form. Let us supply you with the perfect feedstock solutions to accelerate your research and industrial applications.

01

Let’s talk about closing the loop in your manufacturing process with our metal research multitool – rePOWDER.

02

Let’s develop the perfect powder for your thermal spray process – reach out to our experts, by request a quote for your powder requirements.