In this article, you will learn:

1. What are the applications of chemical etching?

2. How does the chemical etching process look like?

3. What are the advantages of chemical etching?

4. What are the possibilities of safeETCH?

3D Printing and Chemical Etching

The technology for 3D metal printing is a base for enabling of creation of elements of significant complexity unobtainable prior to its usage. Its application is virtually limitless, but a few industries such as automotive, aerospace and medical are the main benefactors. The first two focus mainly on creating a mass manufactured repeatable components, whereas the medical field utilizes the specificity and ability to tailor each printout to unique parameters deriving from anatomical differences between each person.

Creating each element follows the same basic principles, regardless of its intended use. These principles include designing the part with the intended geometry, accounting for thermal shrinking, and using supports. Although supports might seem excessive in a finished component, they are essential for preventing deformities during the manufacturing process. Supports can be removed through metal machining processes. However, these methods can be costly, time-consuming, and prone to defects. Chemical etching offers a better alternative.

Chemical Etching Process

Various industries use chemical etching, such as glass processing, jewelry, forensic science, and more. Its application in metal etching, combined with 3D metal printing, has significantly increased in recent years. The chemical etching process for 3D printing postprocessing involves removing undesired parts of printouts (supports) using specially selected solutions of acids, bases, or salts. These solutions are usually aqueous but sometimes organic solvents. They are tailored to the sample size, geometry, and type of element or alloy composing the desired part. Several advanced chemical etching techniques utilize additional factors, such as:

– Electric currents (electroetching)

– Photosensitive masking or activators (photo etching)

– Gas reagents instead of solutions (gas phase etching)

– Temperature (temperature-regulated etching chemicals)

Advantages of the Chemical Process

The main benefit of using a chemical process over a mechanical one is the ability of solutions to penetrate even the most complex geometries of the samples. Some of these geometries would be impossible to reach with other tools. The wet etching process typically includes one or two types of specially designed baths. The part is submerged in these baths for a specific time, forming the core of the etching process know-how.

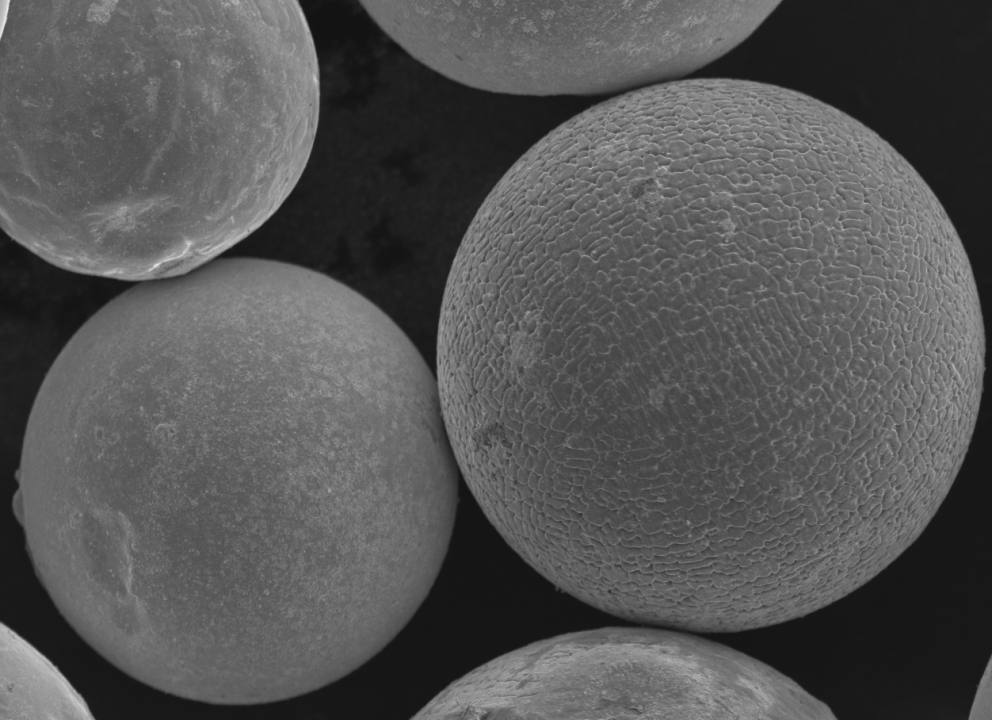

The etching process occurs on the metal surface. It forms a specific soluble salt of the etched element and byproducts, usually in gas form. The formation of gases directly impacts the etching time and performance. This is due to the nature of the reactions and the need for active ions from the solution to be in close proximity to the solid metal surface. Insufficient mixing or lack of degassing can result in slow etching rates. Materials may be classified as having strong etch resistance when the etching device is incorrectly operated. To eliminate this influence, AMAZEMET developed the safeEtch device using ultrasonic transducers.

AMAZEMET Chemical Etching Services

AMAZEMET holds a patent for the safeEtch device for safe support removal. It also holds two application patents for etching aluminum, titanium, and their alloys. The device can be safely operated without the risks typically associated with handling aggressive chemicals in traditional chemical etching equipment. Thorough research has been conducted on the types of chemicals used and their concentrations resulting in solid know-how of the process. This knowledge enables the design of etching processes with good control over etching rate, time, and changes to the metal surface.

For titanium and its alloys, the process uses oxidizing acid and aqueous solutions of salts. These salts donate anions to a complex and multistep chemical reaction. This reaction generates gaseous byproducts. Bubbles and cavitations created in the liquid hinder further reactions between ions in the solution and the metal surface. Ultrasonic transducers counteract this by producing vibrations at the kHz level. These vibrations greatly accelerate gas removal and mix the solution, providing uniform concentrations of reagents.

Ultrasonic vibrations benefit etching processes by increasing stability and delivering more repeatable outcomes. This occurs regardless of printout geometry. After the process, chemically etched samples are rinsed with water and become safe for handling.

Besides chemical etching for support removal, the safeEtch device can conduct polishing. Some samples, after printing, have discolorations or are covered in fine metal particles. These particles greatly diminish their visual appeal and can create unwanted roughness. Polishing can significantly improve the surface of printouts or create a metallic glow. It can be safely performed using the same chemicals within the safeEtch device.

Summary

In conclusion, our etching process know-how enables us to tailor the process for each specific element after conducting experiments. We can also suggest using different types of supports. This can improve the product’s quality after chemical etching. It is worth noting that poorly designed supports can cause issues even after etching. They leave markings on the element’s surface that may be difficult to remove.