Metal Powder Recycling: A Guide to Sustainable Additive Manufacturing

Powder waste is a costly problem in additive manufacturing. Discover how effective metal powder recycling with Powder2Powder can increase sustainability and save money.

AMAZEMET Introducing a New Business Line: Atomization Service for R&D

WARSAW, POLAND - July 21, 2025 AMAZEMET, a company advancing research and development in materials science and additive manufacturing, today announced the official launch of its new business line: Atomization Service. This on-demand service is designed to provide researchers with cost-effective, small-batch production of high-quality, custom metal powders. Figure 1 Ultrasonic atomization with Plasma (left) and Induction Melting (right) using rePOWDER "We saw a clear challenge in materials innovation. Researchers with brilliant ideas were being held back by prohibitive costs and the inability to procure small, experimental batches of high-quality spherical powders. Our new service directly [...]

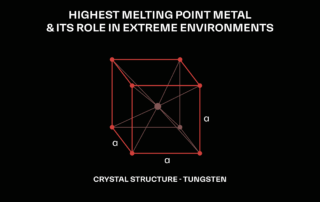

What Metal Has the Highest Melting Point And Why It Matters in Extreme Environments

Tungsten is the highest melting point metal. We break down why it's vital for extreme environments and how our tech enables its production.

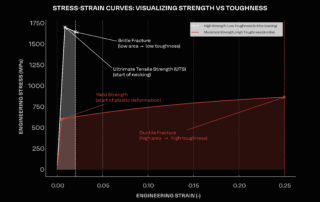

Hardness vs. Toughness vs. Strength: Understanding Key Differences in Material Properties

Hardness vs toughness? Strength vs. hardness? We break down the key differences and why they're critical for engineering safe, reliable components.

7 Types of Additive Manufacturing – Different Methods and Examples

We are excited to announce AMAZEMET’s participation in the 14th International Conference on Hot Isostatic Pressing (HIP 2025), taking place from April 6 to 10, 2025, in Aachen, Germany.

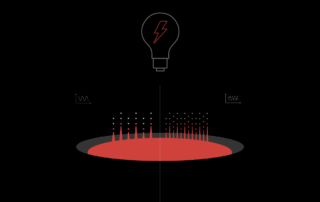

Energy Requirement for Metal Atomization Process

The energy requirement for metal atomization process is a critical in AM. Our rePOWDER platform is up to 10x more energy-efficient than traditional methods

From custom powders to 3D printed metal part | Application note

Ultrasonic atomization, featuring the rePOWDER system, addresses the challenge of high-cost precious metal powder production for additive manufacturing. This technology efficiently processes small batches of materials like silver, gold, and PGMs, yielding high-quality, spherical powders with excellent flowability and remarkable material recovery.

Stereologically corrected particle size distributions for polymer-mounted additive manufacturing powders

Authors: Tomasz Borowski, Katarzyna Zielińska, Maciej Spychalski, Bogusława Adamczyk-Cieślak, Łukasz Żrodowski