High entropy alloys from pure elements | Case study

High entropy alloys are hard to obtain due to often usage of refractory elements. Thanks to the fact that arcMELTER can be equipped with focus plasma torch working with such elements is much smoother than just standard TIG torch. Additionally with the use of inFURNER you can perform the test of anneling time influence and thermal stability of HEA microstructure in casted state, powder form obtained by rePOWDER of after your powder-based manufacturing process.

Low volume production of superalloy powders | Application note

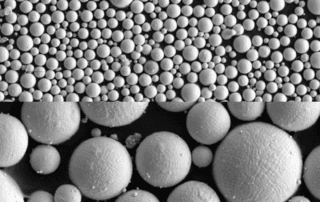

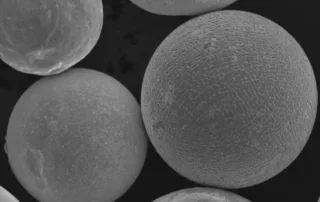

Produce spherical superalloy powders from just 10g of feedstock. Explore low-volume, high-value Pt-based powder production with rePOWDER.

Bioresorbable metal powders for additive manufacturing | Application note

Bioresorbable metal powders enable implants that safely degrade in the body, offering major benefits for biomedical applications. In the 3D-BioMg project, AMAZEMET develops spherical magnesium-based powders to support next-generation implant design.

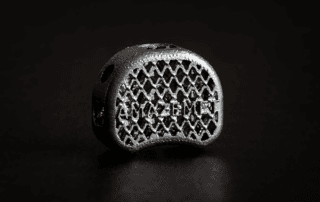

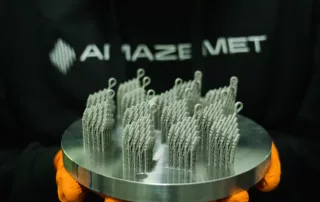

From custom powders to 3D printed metal part | Application note

Develop custom alloy powders for additive manufacturing to achieve better performance, lower waste, and enable new 3D-printed metal parts.

Metal Powders for Additive Manufacturing

Vestibulum ac diam sit amet quam vehicula elementum sed sit amet dui.

AMAZEMET’s Pioneering Research in Metallic Glasses and AM

In this article you will learn How does the publication in the Journal of Additive Manufacturing introduce a new strategy for creating crystalline-amorphous composites using metallic glasses? How does the research contribute to the fields of materials engineering and additive manufacturing? What are the key highlights and findings of the research on Laser Powder Bed Fusion (LPBF) of metallic glasses and their composites? What challenges and breakthroughs in LPBF does the research address? How does the research pave the way for the practical application of bulk metallic glasses (BMGs) and Metallic Glass Matrix Composites (MGMCs) in engineering and manufacturing? [...]

AMAZEMET and WUT Racing Partnership

In this article you will learn What is the nature of the partnership between AMAZEMET and WUT Racing? How does AMAZEMET contribute to WUT Racing’s efforts? What happened during Formula Student Poland competition? What are the future plans for this collaboration? Empowering WUT Racing’s Aspirations In the realm of engineering, collaborations can significantly enhance learning and application. This is evident in the partnership between AMAZEMET, known for its focus on additive manufacturing, and WUT Racing, a team of engineering students from Warsaw. This collaboration is a practical exploration of how 3D metal printing can be innovatively used in building [...]

FORMNEXT 2023: AMAZEMET impactful presence

Vestibulum ac diam sit amet quam vehicula elementum sed sit amet dui.

Materials for 3D printing – Ultimate Guide

Vestibulum ac diam sit amet quam vehicula elementum sed sit amet dui.

What is rapid prototyping? Innovative Product Development

Vestibulum ac diam sit amet quam vehicula elementum sed sit amet dui.